Benefits

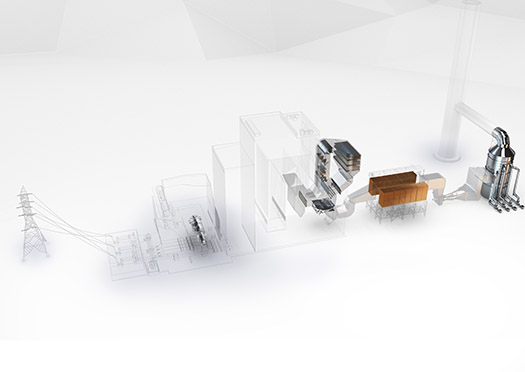

Solutions for power generation and industrial applications

The GE SCR system including ammonia injection, mixing system and unique design features offer the lowest operation cost in combination with high performance and high reliability.

Lowering NOx throughout the combustion process

GE’s Selective catalytic reduction (SCR) technology controls NOx formed in combustion processes. With more than 30 years of experience with SCR technology for power generation and industry applications, GE’s lower cost DeNOx solutions help customers reach their requested performance levels.

Key features of NOx control:

- More than 49 GW installed with more than 80 installations

- Up to 95% NOx removal, low ammonia slip (less than 2 ppm)

- Proprietary IsoSwirl™ mixing technology and specific ammonia injection grid design for improved performances

- Mercury oxidation capability can be included

- Design for superior flow distribution

- Economizer by-pass to be included if needed

- Relationships with leading catalyst suppliers

Specifications

Our selective catalytic reduction technology

| Simple Cycle | |

|---|---|

| Reactor size(m3/h) | up to 5,400,000 |

| Fuel type | Gas, fuel, oil, orimulsion, petroleum coke, biofuel (virgin wood or peat), coal |

| Reactor postition | High dust SCR for power plants and CHP plants; tail end SCR for power plnats and industrial applications |

| Reactor flow direction |

|

| Cleaning method | Soot blower using steam or compressed air, sonic air horns, air sweepers |

| NOx Removal efficiency (%) | Up to 95 |

| NH3 Slip (ppm) | 2 |

| Operation temperature(oC) | 330 – 435 for coal/oil 230 – 454 for gas 200 – 300 for tail end solutions |

| NOx Inlet concentration (ppm) | 1,000 |

| O2 (%) | 1 (minimum) |

| SO2 (ppm) | up to 3,500 |

| SO2/SO3 Conversion(%) | 0.5 – 2.0 |

| ASH load (md/Nm3) | up to 35,000 |

| Reagent type | Anhydrous ammonia, aqueous ammonia, urea |

Hear from our customers

-

Emissions control for Portugal

-

Emissions control for Portugal

Emissions control for Portugal

NOx removal efficiency

In July 2008 EDP, the main power producer in Portugal chose GE’s SCR technology to retrofit their power station of Sines with four new SCR units. These SCR units are designed for 81% NOx removal efficiency and use heated ammonia solution as the reagent and a vanadium/titanium honeycomb catalyst. With these SCR units, Portugal has become one of the few countries in Europe to have equipped all of its coal-fired plants with systems to control both SOx (sulfur oxides) and NOx, thus meeting European Union emission targets.

Our products

More AQCS products to meet your needs

Small-sized AQCS applications

GE’s Smartline range of products caters to small-sized air quality control applications such as district heating, small power units, thermic fluid heaters, limekilns, foundries, and metallurgical plants.

Learn more