Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

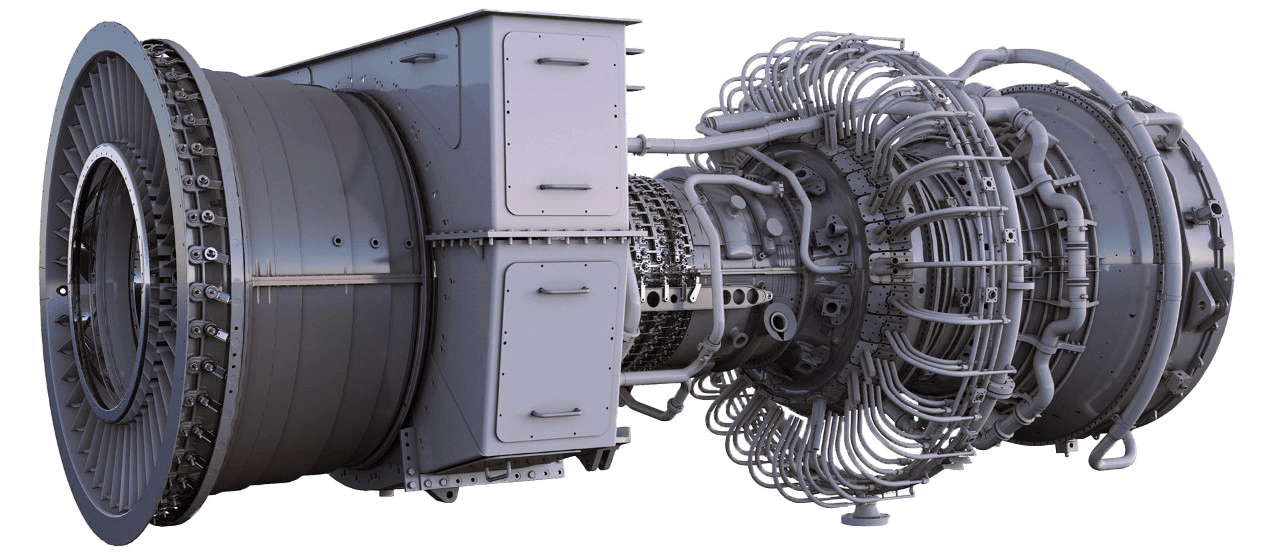

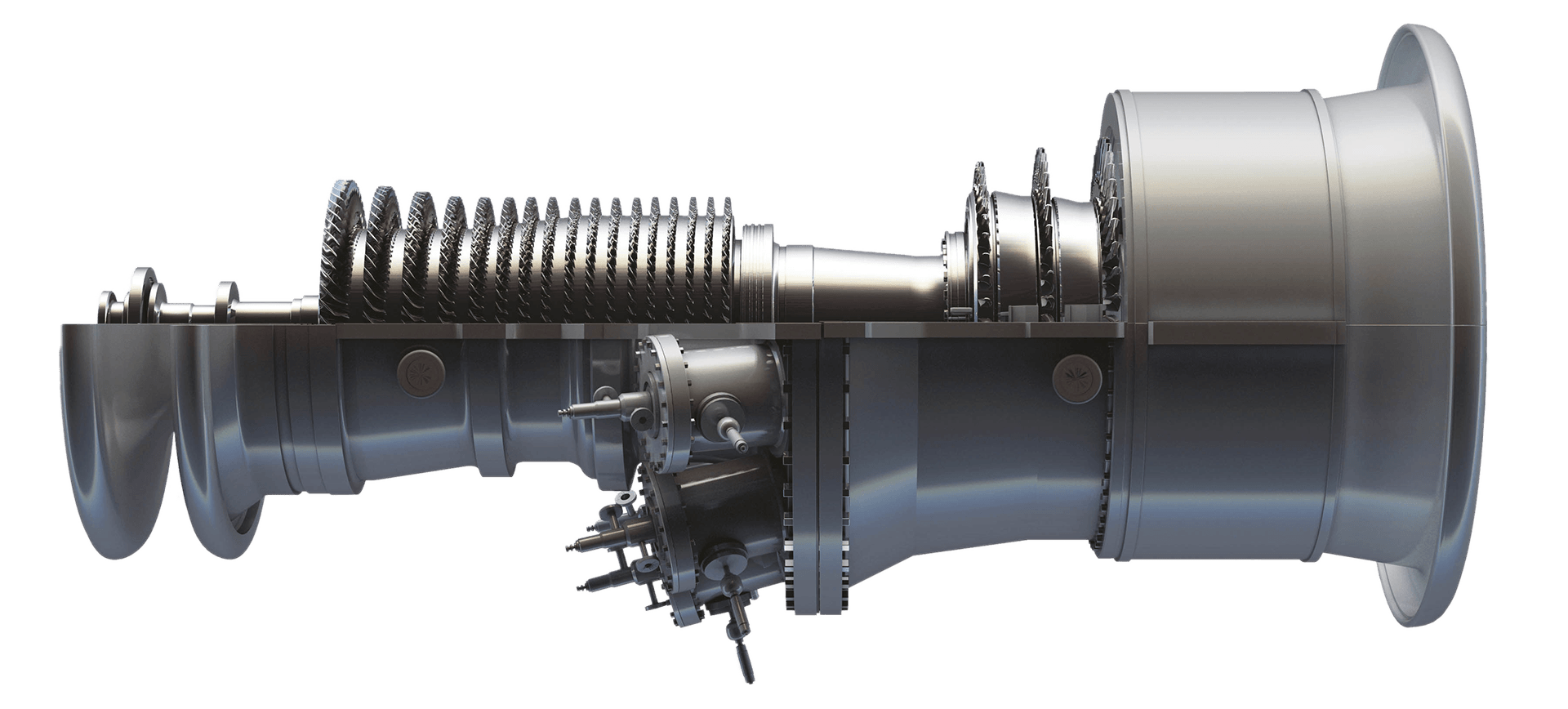

9E gas turbine

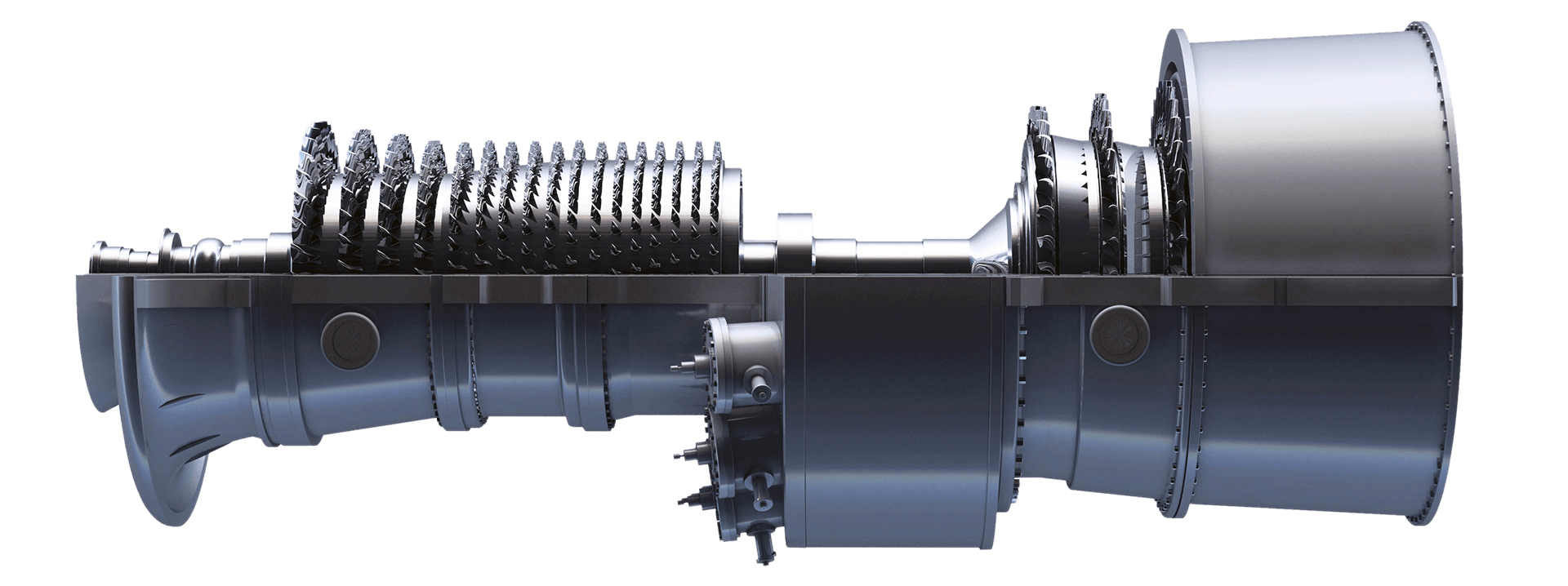

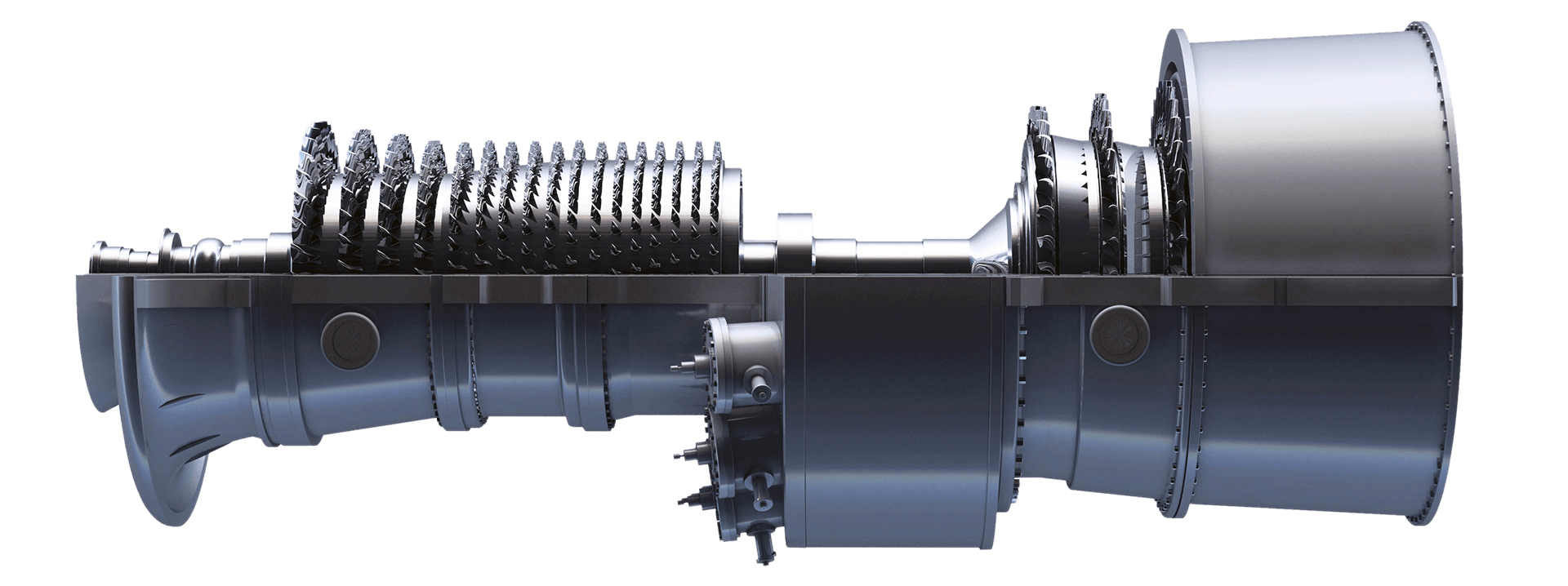

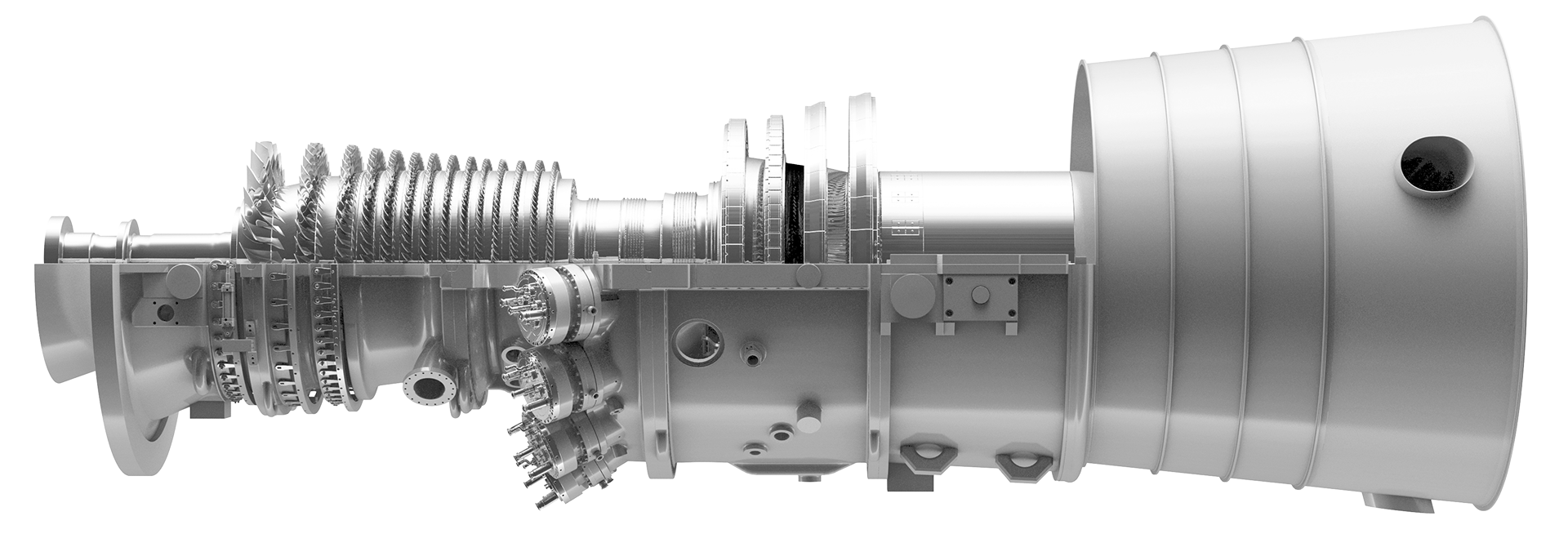

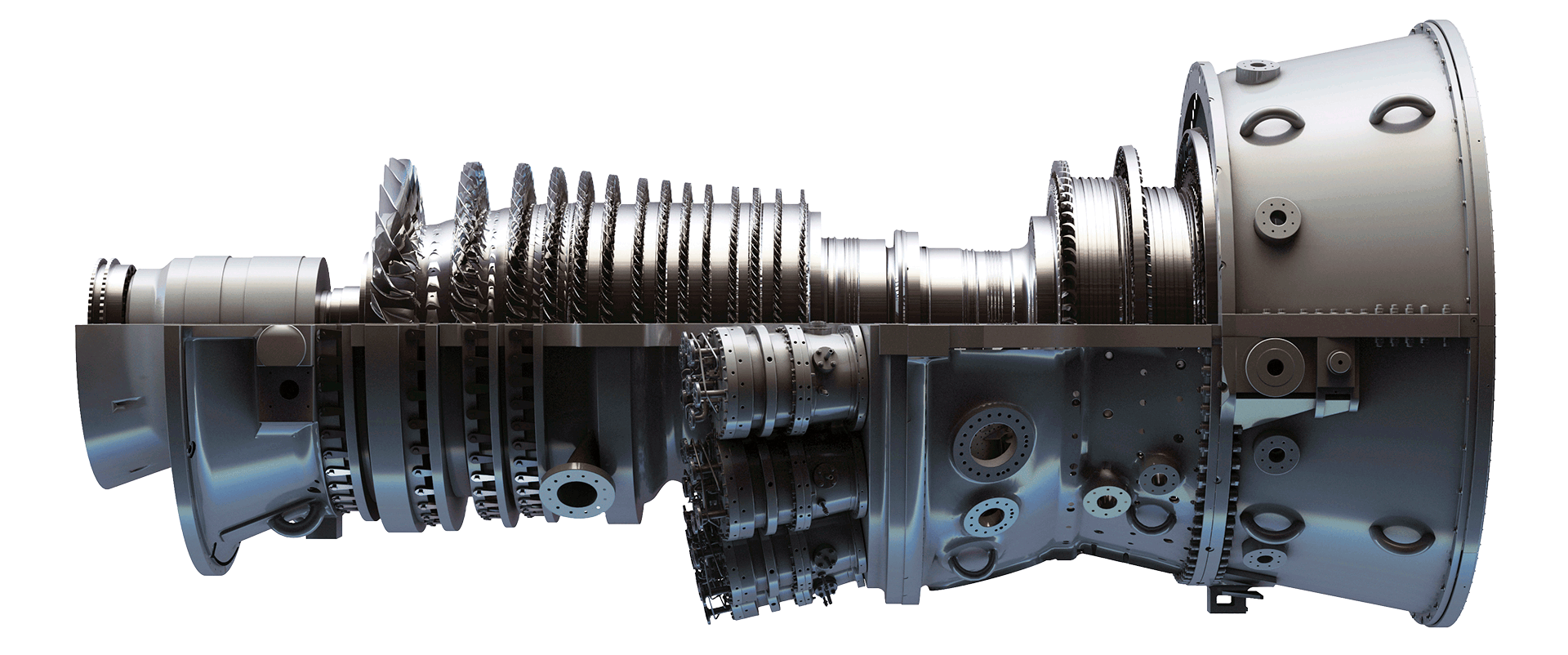

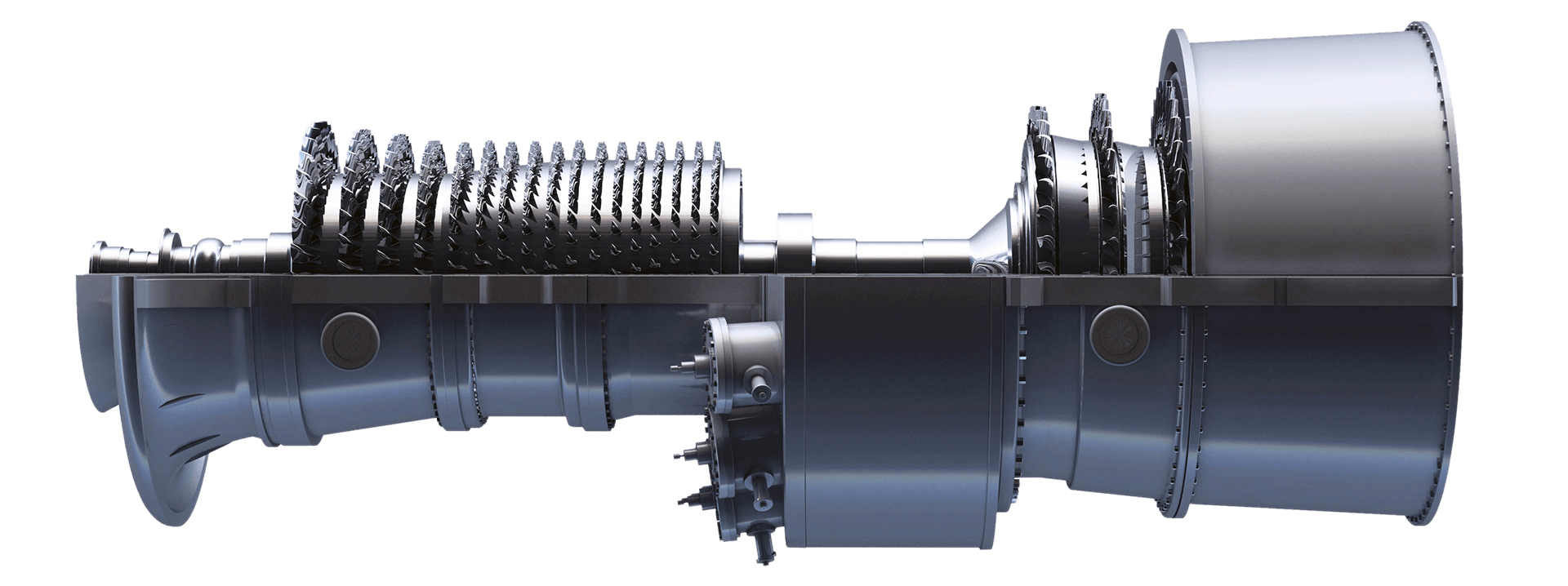

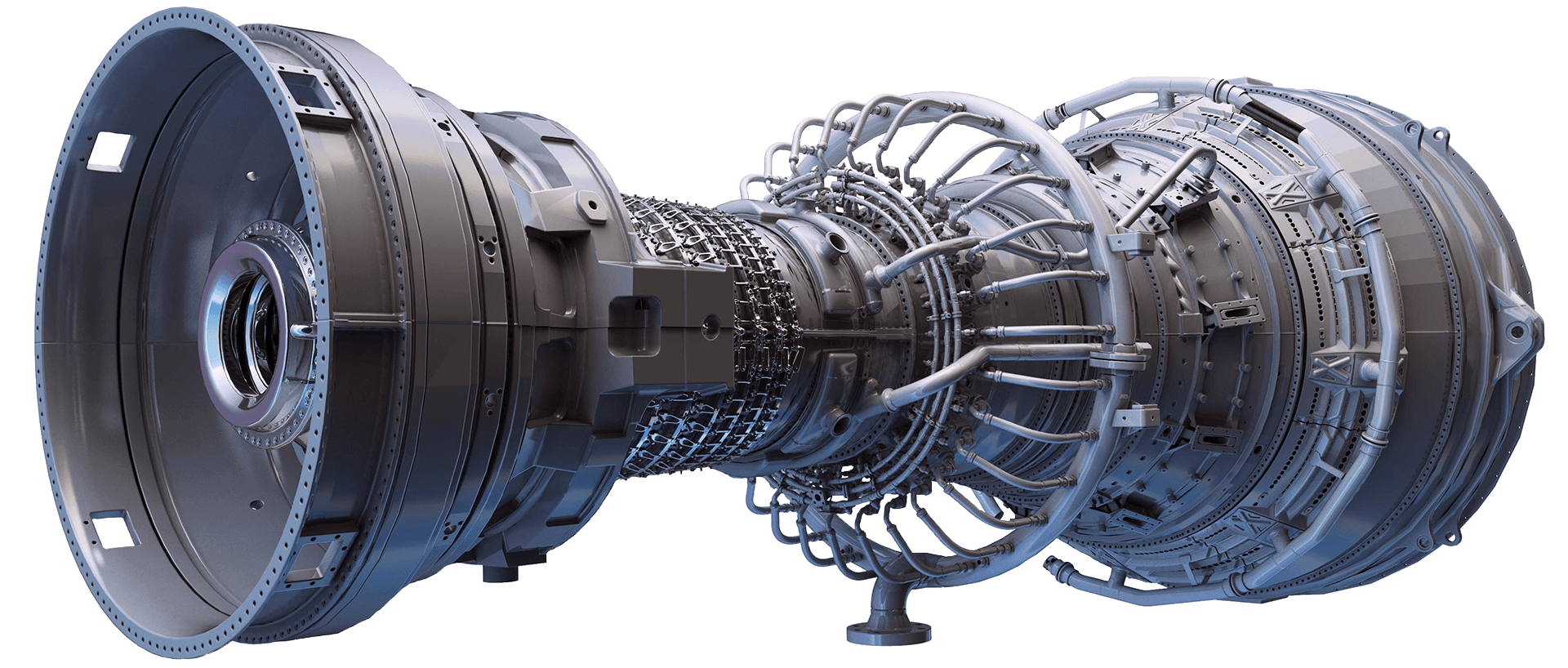

Formerly known as the Frame 9E, GE Gas Power’s 9E gas turbine can help decrease costs and increase revenue for your plant.

From the desert to the tropics to the arctic, the rugged 9E.03 heavy-duty gas turbine provides essential power and performs in a vast number of duty cycles and applications. The 9E.04 gas turbine provides increased power and performance while maintaining the simplicity and operational strengths of the 9E.03.

132–147 MW

simple cycle output

>55%

combined-cycle efficiency

<6 months

order to operation demonstrated in fast track SC projects

50+

types of fuels burned

Explore the 9E

9E gas turbine features and benefits

The 9E is a robust, proven platform that helps deliver high availability, reliability, and durability while lowering the overall cost-per-kilowatt.

Providing the widest range of fuels experience

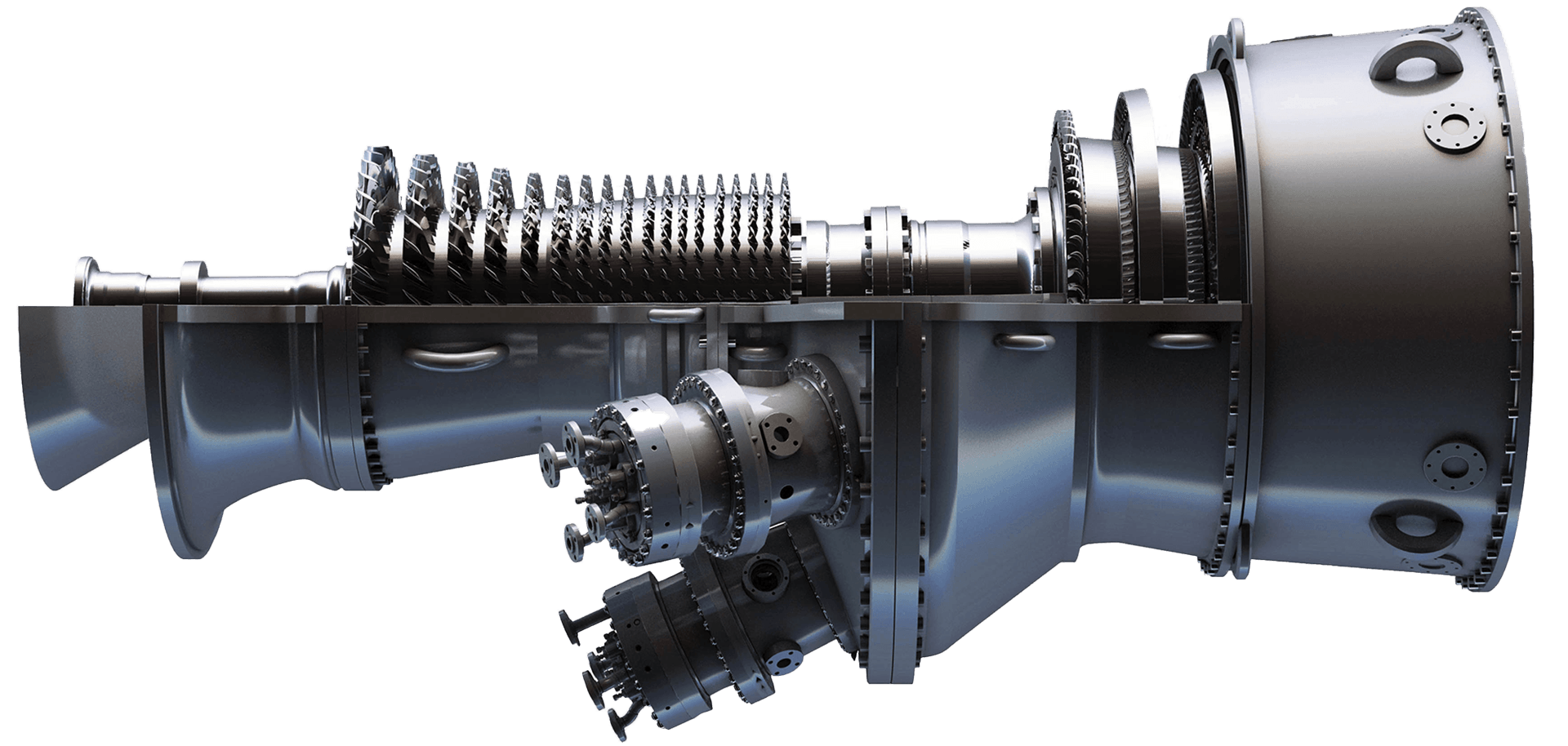

9E gas turbines can use more than 52 types of fuel— almost the entire fuel spectrum—and can even switch fuels while running under full load. Our 9E turbines operate on fuels with contaminants, natural gas, light and heavy distillate oil, naphtha, crude, residual oil, syngas, and steel mill/blast furnace gases.

Rapidly getting you from decision to delivery

With order to simple-cycle operation demonstrated in as few as six months, and fast-start and load capabilities, the 9E gas turbine has quick installation and operational flexibility.

9E.04 gas turbine: Enhanced power and performance

The 9E.04 gas turbine has multiple features that help reduce fuel costs and increase revenue, such as a 145 MW output and 37% simple-cycle efficiency.

A proven performer

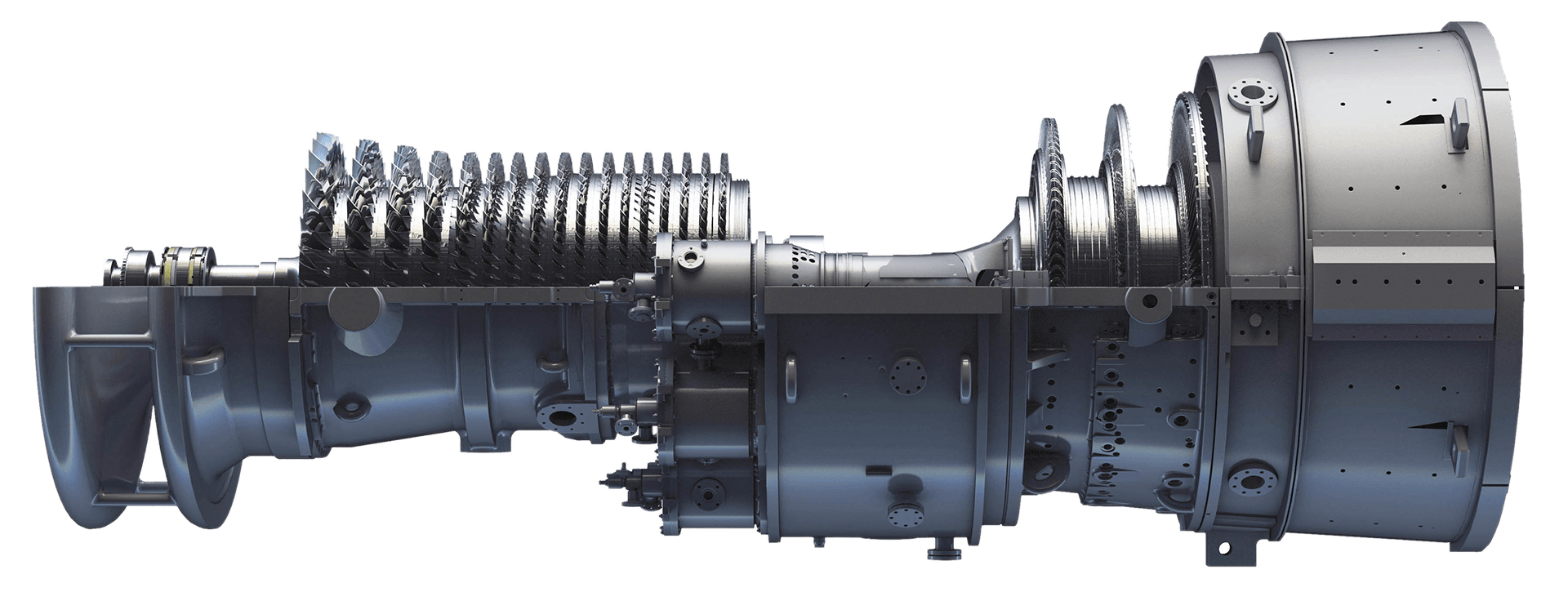

The 9E gas turbine utilizes proven E- and F-class materials, fired at lower E-class temperatures for hot gas path, with cooling and sealing improvements, improved clearances and improved work splits between stages.

It’s a strong performer in a variety of scenarios, including simple-cycle, combined-cycle, and industrial CHP and mechanical drive applications in a broad range of industries, including electrical utilities/independent power producers, industrial oil and gas refineries, IWPP, aluminum industry for smelting, steel mills, and LNG.

Lowered emissions and enhanced features

The 9E gas turbine boasts Dry Low NOx (DLN) combustion with 5ppm NOx* and 25 ppm CO with around 30% Modified Wobbe Index (MWI) flexibility, and emissions standards that help meet World Bank requirements, including dual-fuel heavy fuel oil plants.

The 9E.04 gas turbine features a new 4-stage turbine module that fits within the same footprint as an already installed 9E gas turbine unit. Additionally, it has a 17-stage compressor with corrosion-resistant material, coatings, and inner barrel brush seals that can enhance compressor durability. Its compact footprint helps it create an easy incremental power addition when phased capacity expansion is required.

*Assumes ultra-low NOx option is chosen

Specifications

Power and performance

Get an inside look at the 9E gas turbine’s product specifications

Specifications shown are 50 Hz

| 9E.03 | 9E.04 | |

|---|---|---|

| Net output (MW) | 132 | 147 |

| Net heat rate (Btu/kWh, LHV) | 9960 | 9238 |

| Net heat rate (kJ/kWh, LHV) | 10508 | 9747 |

| Net efficiency (%, LHV) | 34.3% | 36.9% |

| Ramp Rate (MW/minute) | 50 | 29 |

| Startup Time (RR Hot, Minutes) | 30 | 30 |

9E series gas turbines can run on 52 types of fuel.

NOTE: All ratings are based on ISO conditions and natural gas fuel. Actual performance will vary with project-specific conditions and fuel.

Customer stories

-

West Africa Energy—becoming Senegal’s biggest plant

-

Wuhan Iron and Steel grows its operations—responsibly

-

Helping mitigate shifting dynamics in Japan

-

West Africa Energy—becoming Senegal’s biggest plant

-

Wuhan Iron and Steel grows its operations—responsibly

-

Helping mitigate shifting dynamics in Japan

West Africa Energy—becoming Senegal’s biggest plant

Senegal is in need of the right gas-power technology to grow its renewables. See how GE’s advanced 9E gas turbines became the core of West Africa Energy’s combined-cycle plant. The 300-MW power plant will soon be the country’s largest—expected to generate nearly 25% of nationally consumed power.

30 MW

of projected total plant power

500,000+

Sengalese homes can benefit

"We are pleased to collaborate with GE to deliver reliable and efficient gas turbines to Senegal, aligning with our strategy of gas to power. This project will go a long way in reducing the cost of electricity in the country.”

Samuel Sarr

CEO of West African Energy

Wuhan Iron and Steel grows its operations—responsibly

In 2007, the Chinese company built the world’s largest blast furnace gas power plant, reusing the mill’s own blast furnace and coke oven waste gases to fuel two GE 9E gas turbines. The Wuhan plant produces 260 tons of steam per hour for steel production and generates 2.4 billion kWh of electricity, with an annual output of 1 TWh. Utilizing waste gas provides a number of benefits, and the mill also saves a great deal of money by generating 164 MW of its own electricity.

>42%

electrical efficiency

2 million tons

reduction in CO2 emissions

"One of the greatest challenges to the steel industry around the world is effectively addressing increased emissions regulations while controlling spiraling costs. This milestone project with Wuhan Iron and Steel will allow BFG flares to be captured with higher efficiency and lower emissions to recycle energy back into the plant."

Jack Wen

GE Gas Power, China

Helping mitigate shifting dynamics in Japan

With nuclear power generation cut almost entirely, Japan has been experiencing difficulty in electricity shortages, especially during peak summer months. Tokyo Electric Power Company (TEPCO) was seeking to upgrade Block 1 of their Futtsu Thermal Power Station. The goal is to boost output and enhance heat rate, all while continuing to use existing steam turbines and generators.

In operation for three decades, the six older 9E gas turbines at Futtsu Block 1 are well-suited for GE’s 9E.04 flange-to-flange solution. This consists of new gas turbine components and a step from three- to four-stage, which increases hot gas components from nine to 12.

combustion efficiency improvements

167 MW

turbine output increase

Further reading

Learn more

9E gas turbine information

9E gas turbine services

Get more for your 9E gas turbine

GE’s Gas Power services team stands ready to collaborate with you in providing solutions that drive your competitiveness, profitability, and productive outcomes. For every customer need, GE is ready to help with the right service solution and product offerings.

Don’t see what you need? Contact us

Products

Find the right gas turbine to meet your needs

Whether you're generating power for entire cities, electrifying your own operations, or are facing an emergency electricity shortage and need power fast, we can act as a versatile gas turbine supplier, ready to quickly provide a range of solutions.

- 50Hz

- 60Hz

- Simple

- 1x1CC

- 2x1CC

- All

- Heavy duty

- Aeroderivative

GE Vernova’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of the world's most efficient combined-cycle power plant.

| 9HA.01 | 9HA.02 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9HA gas turbines are 50% hydrogen (H2) capable with a technology pathway to 100%

With over 450 units deployed to more than 40 countries, GE Vernova has the largest operating and most experienced OEM F-class fleet in the world. Our 9F gas turbine delivers consistent performance and accommodates a diverse range of fuels, making it great for a variety of combined cycle and CHP applications.

| 9F.04 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

9F series turbines are GE’s most advanced F-class technology for 50 Hz applications.

GE’s 7HA high efficiency air-cooled gas turbine is one of the industry leaders among advanced class gas turbine offerings and is available in three models—the 7HA.01 at 290 MW, the 7HA.02 at 384 MW, and the 7HA.03 at 430 MW.

| 7HA.01 | 7HA.02 | 7HA.03 | |

|---|---|---|---|

| Net output (MW) | |||

| Net heat rate (kJ/kWh, LHV) | |||

| Net efficiency (%, LHV) | |||

| Net heat rate (Btu/kWh, LHV) |

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%

The demands of today’s power generation industry are many: low cost of electricity, dispatch volatility, along with high efficiency, reliability, and asset availability. With approximately 950 installed units producing ~175GW of power in 11 countries, GE’s 7F.04 and 7F.05 gas turbines are proven performers in all these areas.

| 7F.04 | 7F.05 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

7F series gas turbines can balance renewables by load-following at 40 MW/min ramp rates while maintaining emissions compliance.

With unprecedented operational flexibility, robust engineering and long operation intervals, the GT13E2 can be used in many different applications—all while meeting a very broad range of environment and operating conditions.

| GT13E2-190 | GT13E2-210 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

GT13e2 gas turbines can run on up to 30% hydrogen fuel.

Formerly known as the Frame 9E, GE Vernova’s 9E gas turbine can help decrease costs and increase revenue for your plant. From the desert to the tropics to the arctic, the rugged 9E.03 heavy-duty gas turbine provides essential power and performs in a vast number of duty cycles and applications. The 9E.04 gas turbine provides increased power and performance while maintaining the simplicity and operational strengths of the 9E.03.

| 9E.03 | 9E.04 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9E series gas turbines can run on 52 types of fuel.

A single, economical solution for the dispatch needs of nearly every industry condition.

| LMS100 PA+ | LMS100 PB+ | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LMS100 gas turbines can start up in 8 minutes

The 7E.03 gas turbine is recognized as an industry leader for 60 Hz industrial power applications. Its robust architecture and operational flexibility make it well-suited for a variety of peaking, cyclic, and baseload operations. With state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path features, the 7E gas turbine can accommodate a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

| 7E.03 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

7E series gas turbines can deliver 100% load in 10 minutes.

GE Vernova’s 6F gas turbine offers the superior performance, reliability, and flexibility typically associated with larger power plants. Our 6F gas turbine packs big power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbine can maintain enhanced output and exhaust energy for combined cycle and CHP performance. The 6F offers segment-leading 32,000-hour combustion and hot gas path inspection intervals.

| 6F | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6F gas turbines offer fuel flexibility and hydrogen capability while maintaining the reliability you’ve come to depend on

A leader in the +40 MW space, the LM6000 has over 40 million operating hours and more than 1,300 units shipped.

| LM6000 PG | LM6000 PF | LM6000 PF+ | LM6000 PC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM6000 gas turbines can start up in 5 minutes

Its ability to operate in island mode, coupled with multiple decades of proven rugged performance, make the 6B an excellent solution for remote installations and extreme operating conditions. The rugged, reliable 6B heavy-duty gas turbine is a popular choice for refineries, natural gas liquefaction power, CHP applications, and industrial power.

| 6B | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6B gas turbines can operate on a wide range of non-standard gas or liquid fuels, including over 90% hydrogen

The LM2500 family of aeroderivative gas turbines boasts several times the operating experience of its competitors combined, and its flexibility and reliability are unsurpassed.

| LM2500XPRESS +G4 DLE | LM2500XPRESS +G5 DLE | LM2500 +G4 DLE | LM2500 +G4 SAC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM2500 gas turbines feature >99.8% availability

Introducing one of the world’s most modular, reliable, and experienced mobile gas turbines.

| TM2500 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

TM2500 gas turbines can be installed and commissioned in 11 days

Former names of GE 9E gas turbines: Frame 9E, 9E, 9E 3-Series, 9141(E), 9151(E), 9161(E), 9171(E), PG9141E, PG9151E, PG9161E, PG9171E, 9E PIP, 9E AGP, 9E Syngas, 9E BFG, MS9001(E)

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more