Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

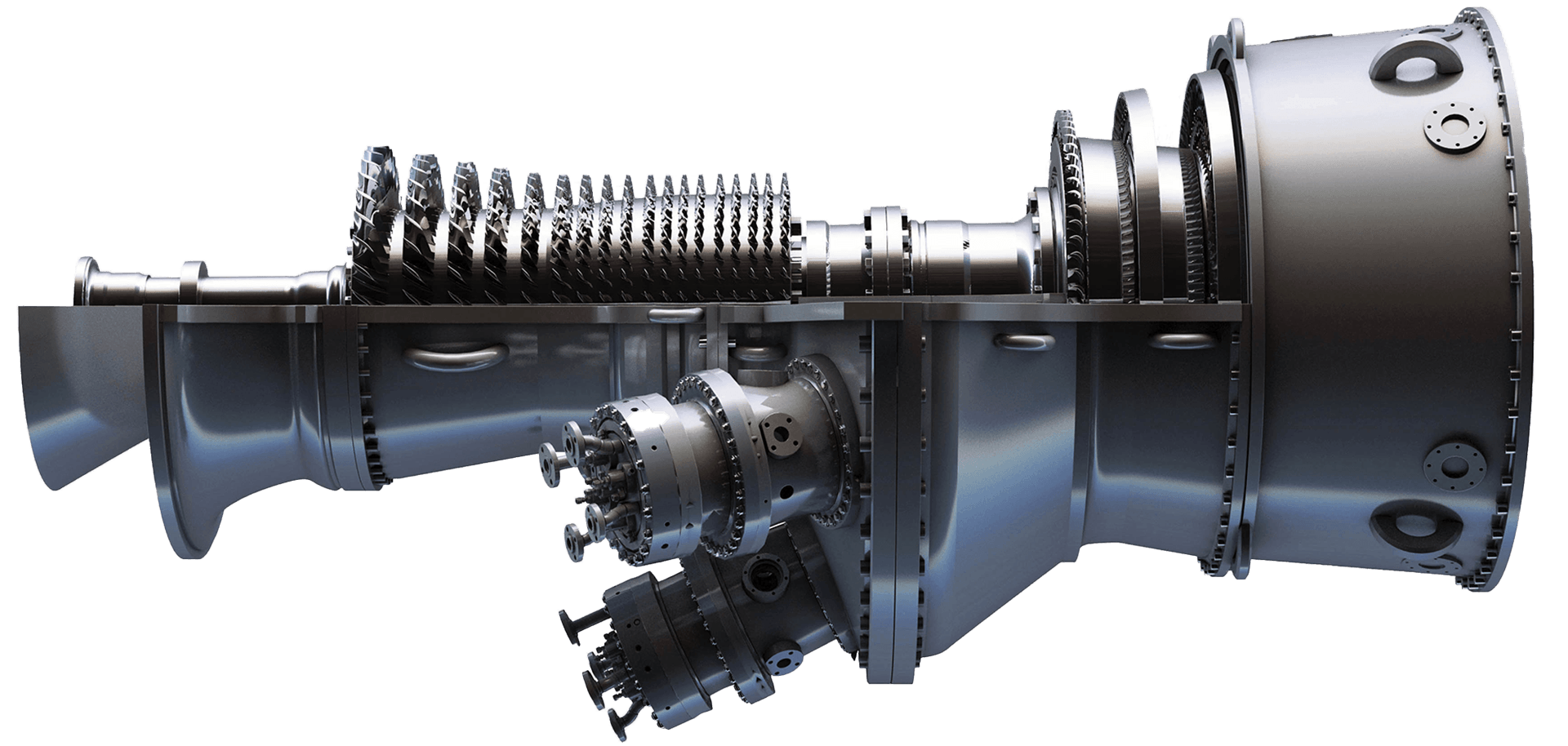

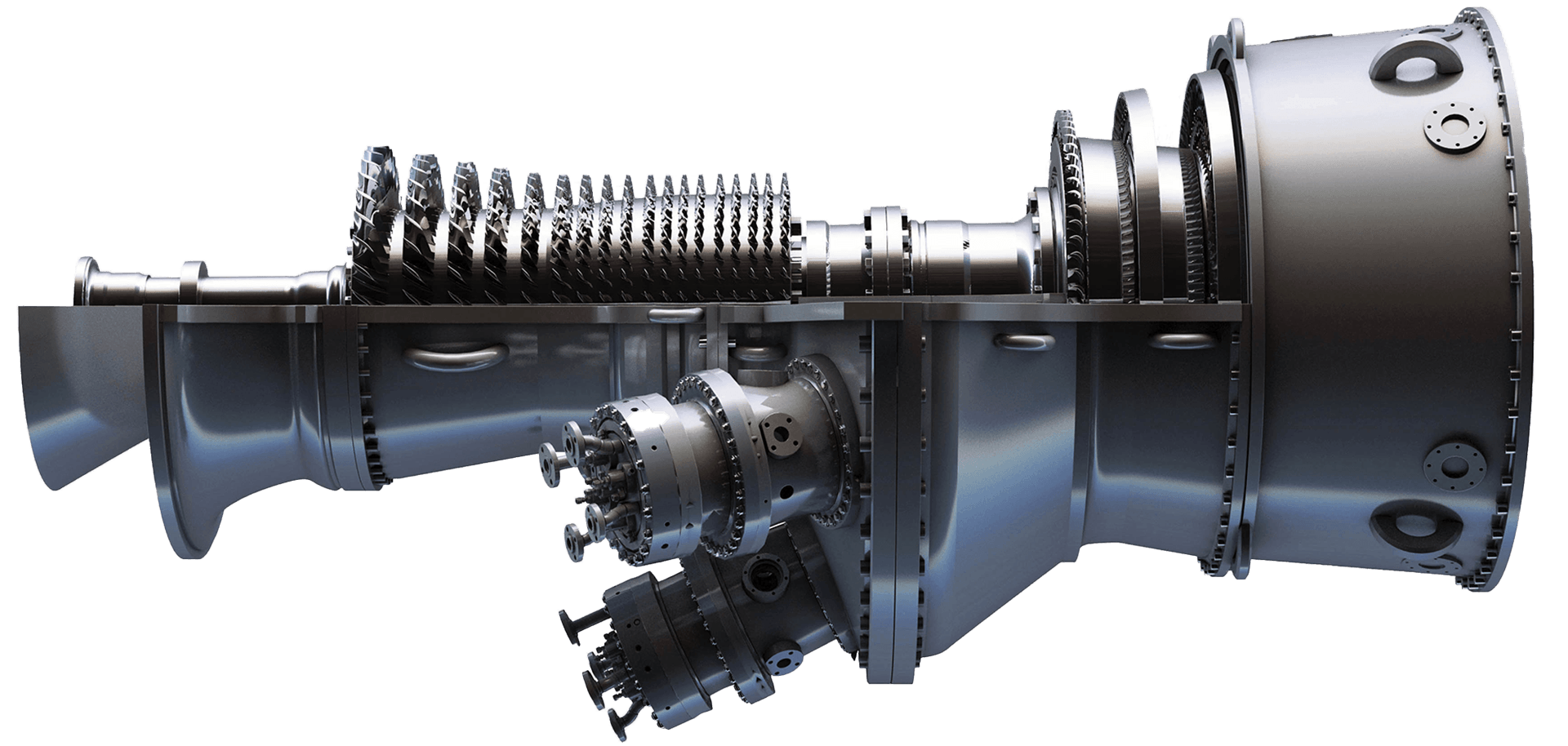

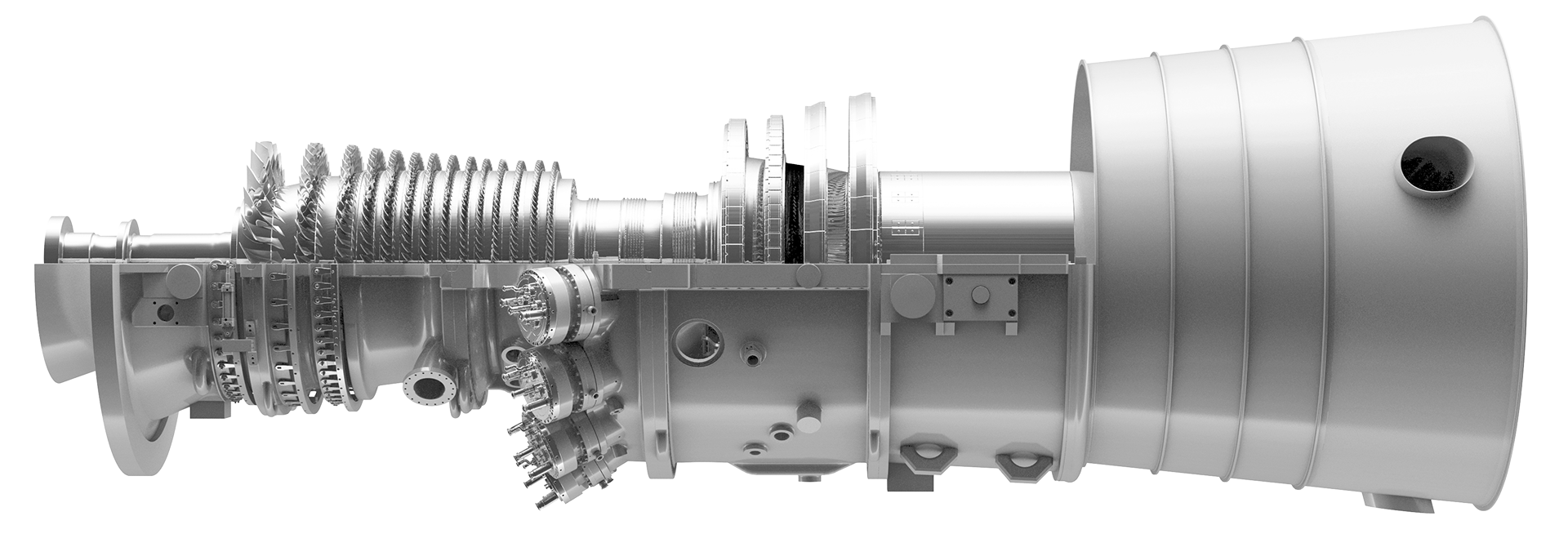

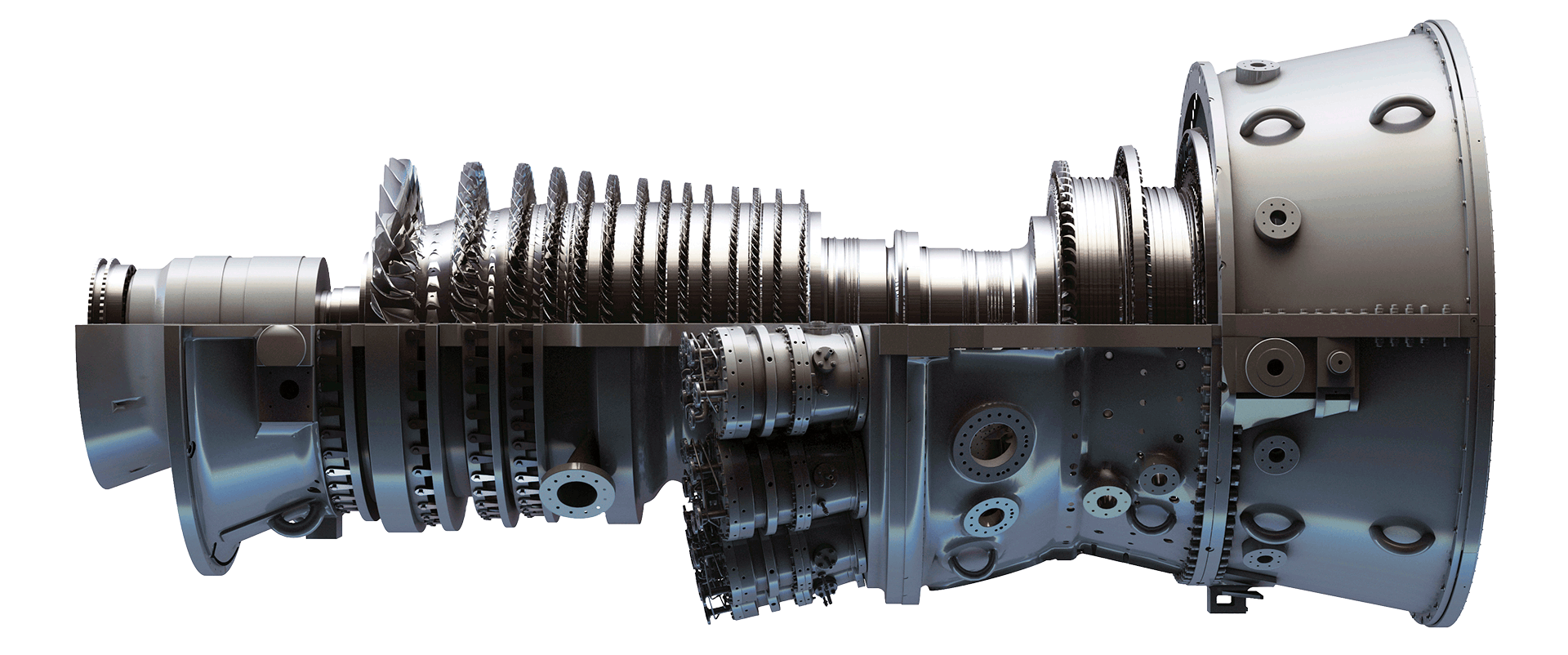

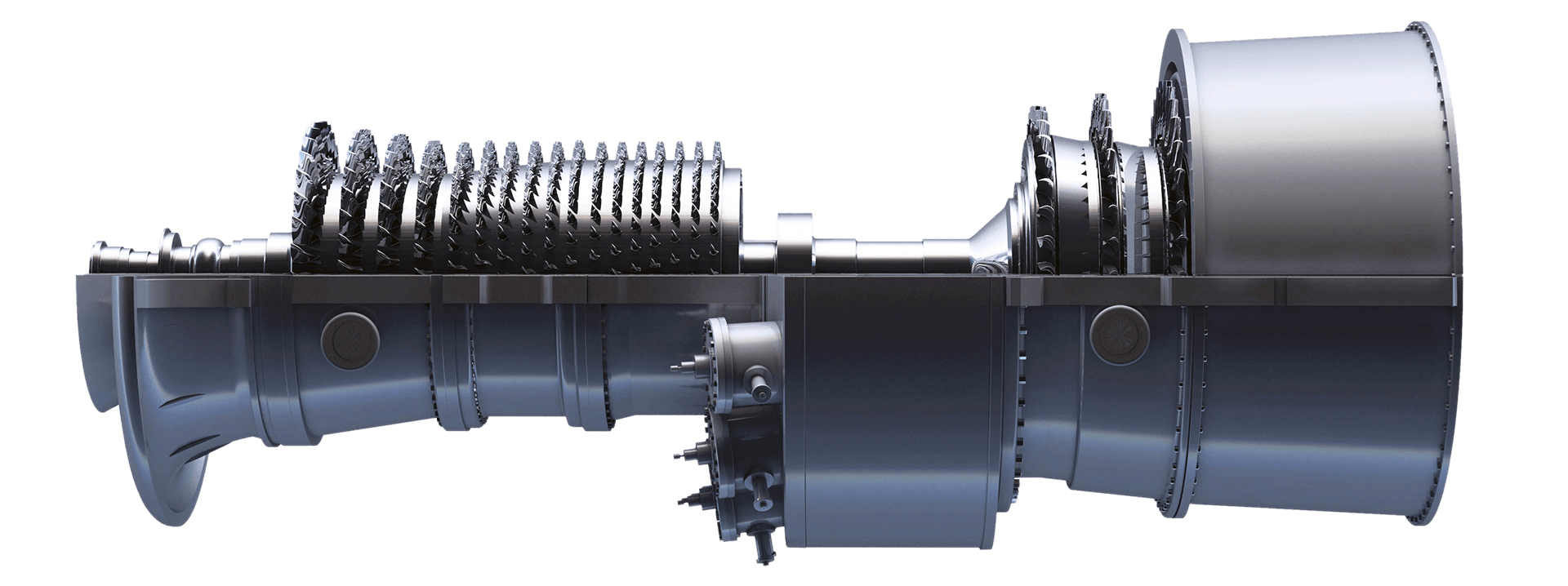

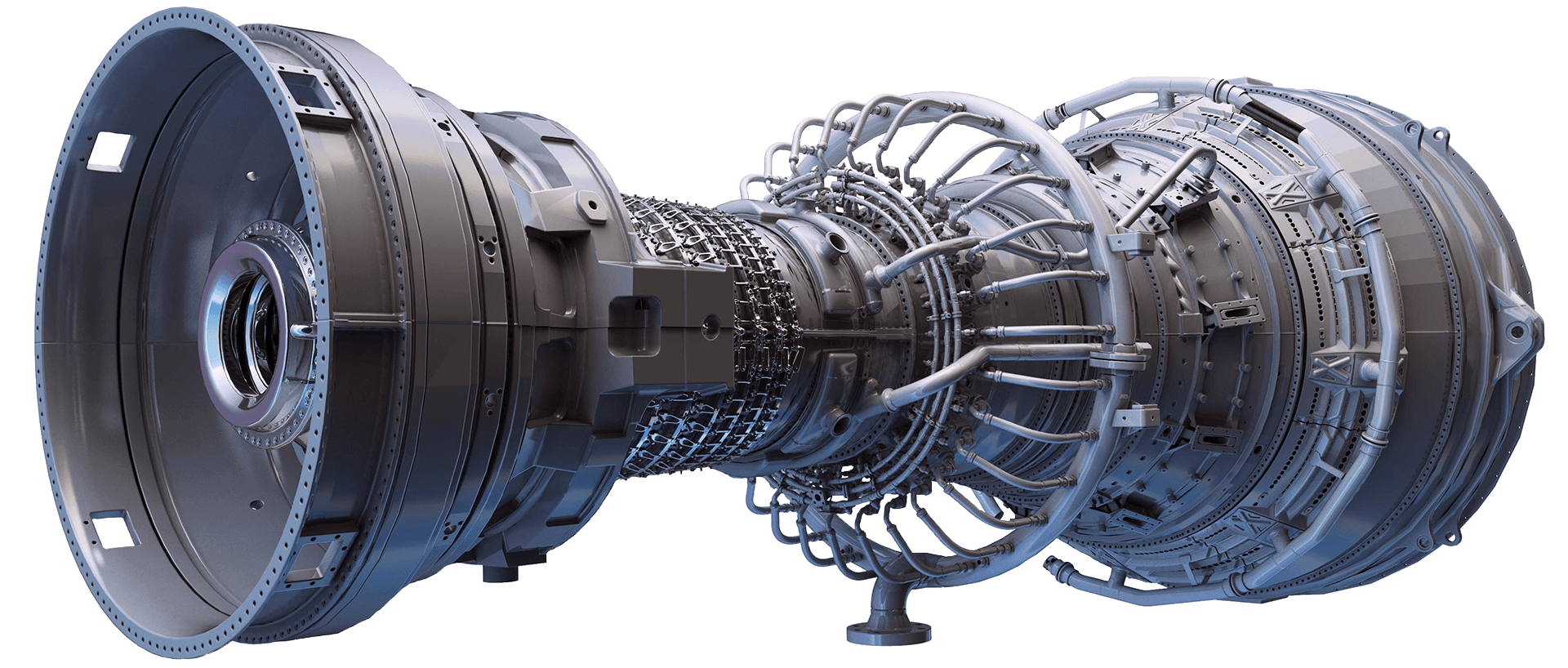

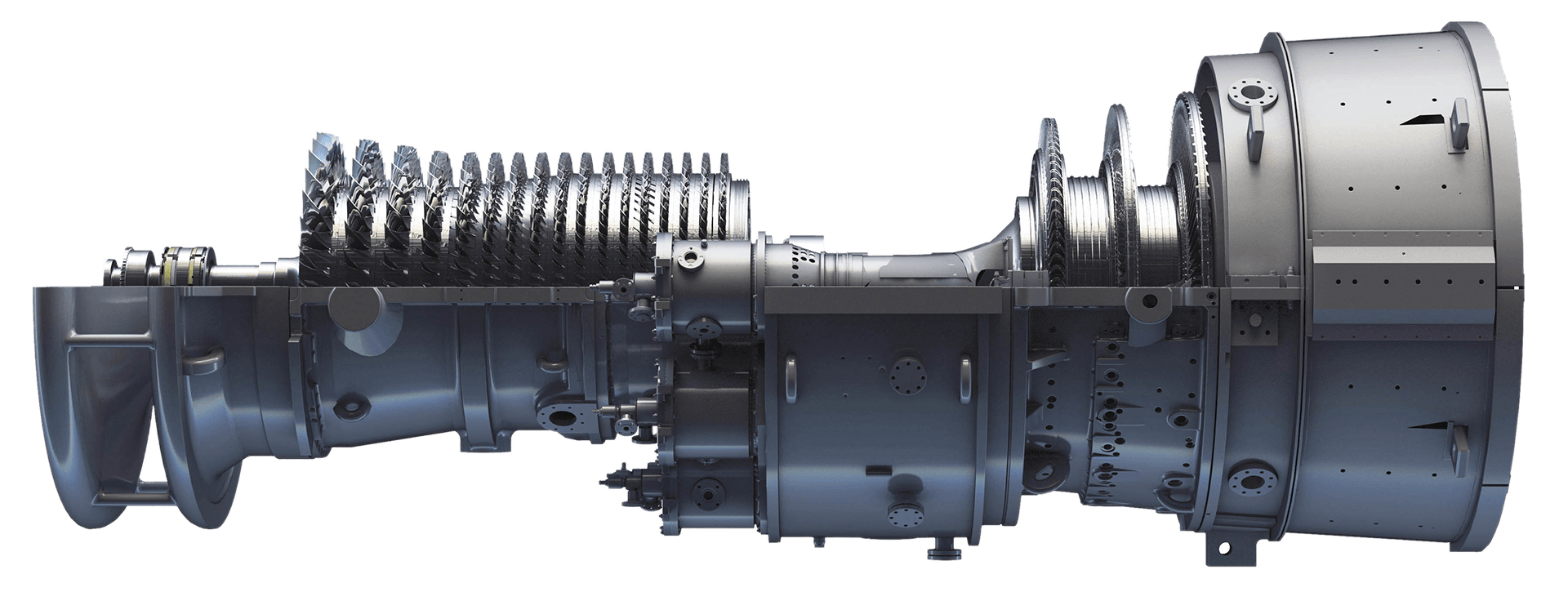

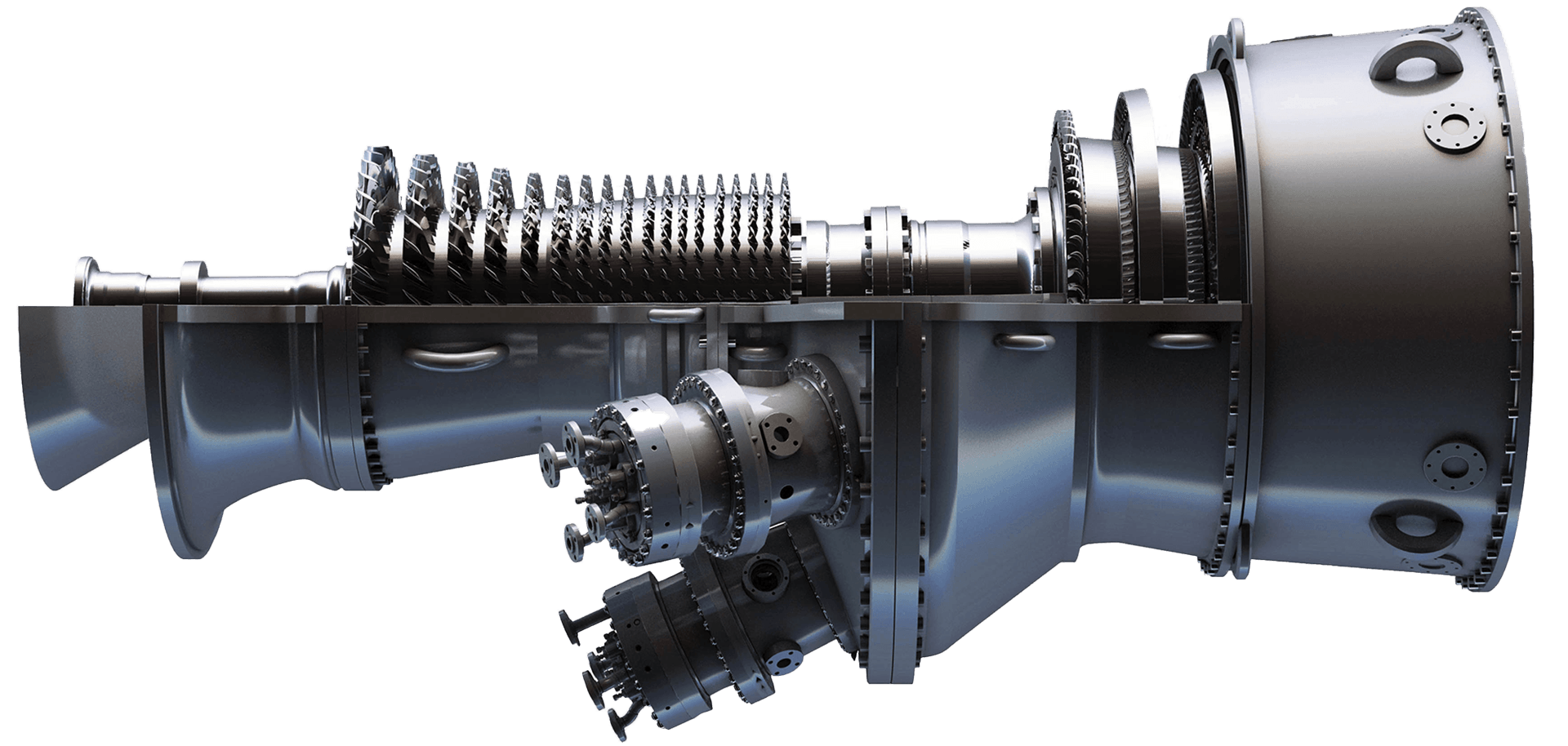

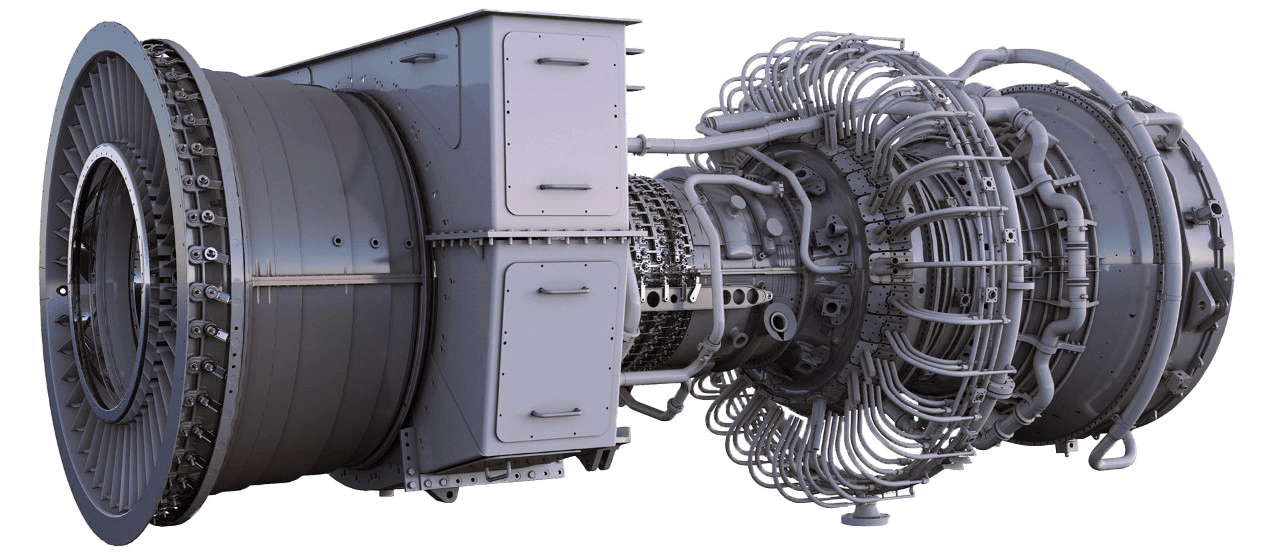

6F.03 gas turbine

GE’s 6F gas turbine offers the superior performance, reliability, and flexibility typically associated with larger power plants. Our 6F.03 gas turbine packs big power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbine can maintain enhanced output and exhaust energy for combined cycle and CHP performance. The 6F.03 offers segment-leading 32,000-hour combustion and hot gas path inspection intervals.

88 MW

simple cycle output

>57%

combined-cycle efficiency

15 ppm NOx

emissions

Up to 100%

hydrogen capability

Two models, lots of power

6F gas turbine features and benefits

With its combination of high efficiency and low emissions, the 6F gas turbine is a reliable, environmentally-friendly choice.

Smaller size, big performance

With GE's 6F gas turbine, plant operators can attain the outstanding performance, reliability, and flexibility typically only seen in larger power plants. The 6F.03 includes GE’s latest in combustion technology for superior flexibility, turndown, and fuel performance. It draws on the best of GE’s scaled H and F-Class technology, offers quick installation, and together with its exhaust energy profile, is an excellent choice for a variety of applications and environments.

Proven experience

The 6F.03 has over 185 units currently in use worldwide, operating in more than 35 countries across Asia, China, Europe, Latin and North America, The Middle East and North Africa, and has accumulated over 13 million operating hours over a span of nearly 25 years.

Fuel flexibility gives you more options

Capable of operating on a wide range of fuels like natural gas, distillate, and synthetic, the 6F.03 can achieve turndown to 35% load using Dry Low NOx (DLN) 2.6 combustion. This DLN 2.6 combustion system enables lower emissions—less than 15 ppm NOx or 9 ppm CO—and 32,000-hour combustion inspection intervals.

Specifications

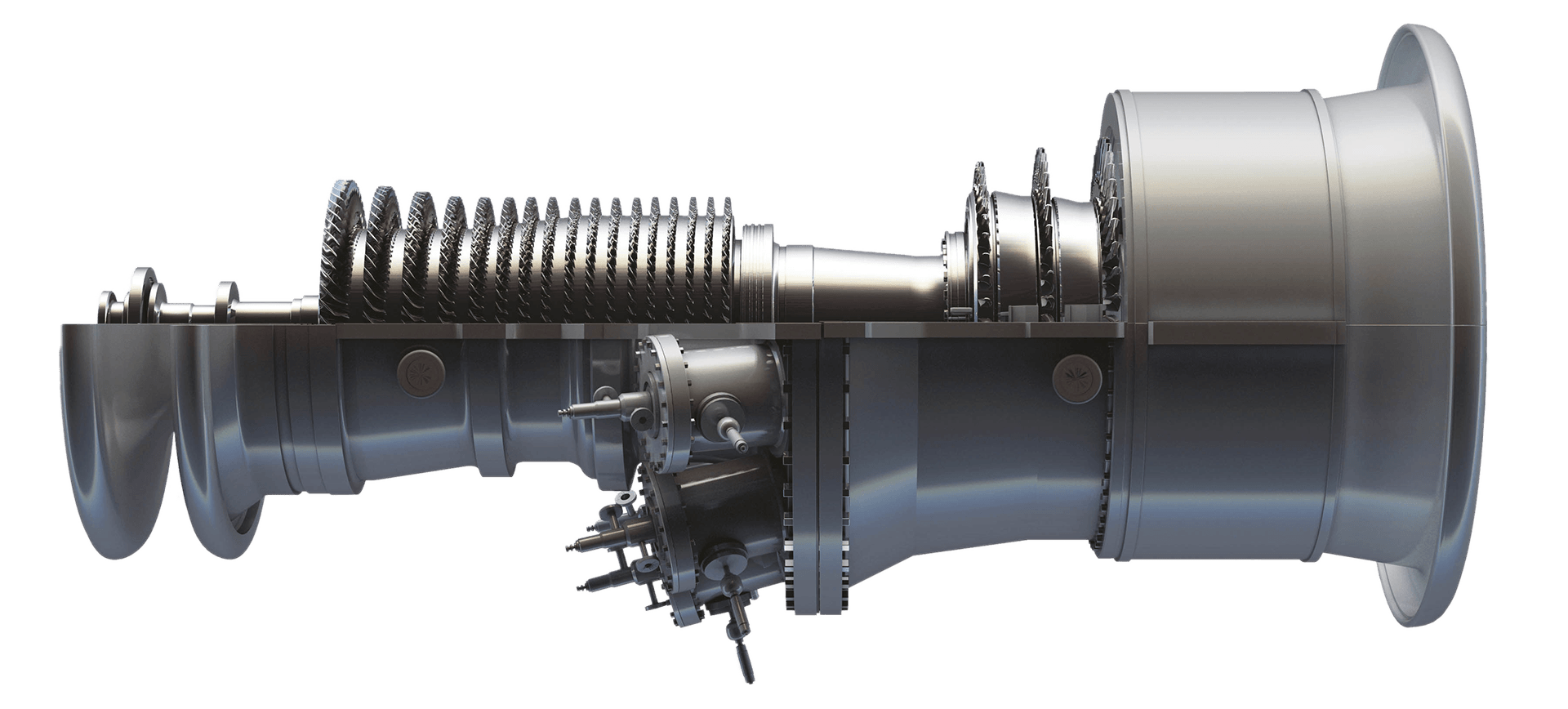

Big power in a smaller package

Get a look inside the 6F gas turbine with our technical specifications.

Specifications shown are for 50 Hz and 60 Hz.

| 6F.03 | |

|---|---|

| Net output (MW) | 88 |

| Net heat rate (Btu/kWh, LHV) | 9277 |

| Net heat rate (kJ/kWh, LHV) | 9788 |

| Net efficiency (%, LHV) | 36.8% |

| Ramp Rate (MW/minute) | 22 |

| Startup Time (RR Hot, Minutes) | 13 |

6F gas turbines offer fuel flexibility and hydrogen capability while maintaining the reliability you’ve come to depend on

NOTE: All ratings are based on ISO conditions and natural gas fuel. Actual performance will vary with project-specific conditions and fuel.

Customer stories

Hear from our customers

South Korea, Asia

KOMIPO’s LNG island generation: A first for GE in Asia

250 MW

total power output

>55%

plant efficiency

"GE’s state-of-art technology and full solution capabilities made them the right choice for our project needs. The 250 MW Jeju power plant will provide reliable and efficient electricity to address Jeju Island’s increasing power needs and contribute to its further growth."

Mr. Changkil Chung

President and CEO, KOMIPO

Customer stories

Hear from our customers

China, Asia

One Gas Turbine type; two different applications

~480 MW

maximum energy output of four plants

~50%

reduced emissions from combined-cycle plant

"The new plant is… expected to improve the energy system of the area and provide a leap forward in the access to natural gas, while helping to meet both power and heat demands from local enterprises.”

Representative

Yangjiang High-Tech Zone Natural Gas CHP Project

Further reading

Learn more

6F.03 gas turbine information

Services

Get more for your 6F gas turbine

GE’s Gas Power services team stands ready to collaborate with you in delivering solutions that drive your competitiveness, profitability, and productive outcomes. For every customer need, GE is ready to help with the right service solution and product offerings.

Don’t see what you need? Contact us

Products

Find the right gas turbine to meet your needs

Whether you're generating power for entire cities, electrifying your own operations, or are facing an emergency electricity shortage and need power fast, we can act as a versatile gas turbine supplier, ready to quickly provide a range of solutions.

- 50Hz

- 60Hz

- Simple

- 1x1CC

- 2x1CC

- All

- Heavy duty

- Aeroderivative

GE Vernova’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of the world's most efficient combined-cycle power plant.

| 9HA.01 | 9HA.02 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9HA gas turbines are 50% hydrogen (H2) capable with a technology pathway to 100%

With over 450 units deployed to more than 40 countries, GE Vernova has the largest operating and most experienced OEM F-class fleet in the world. Our 9F gas turbine delivers consistent performance and accommodates a diverse range of fuels, making it great for a variety of combined cycle and CHP applications.

| 9F.04 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

9F series turbines are GE’s most advanced F-class technology for 50 Hz applications.

GE’s 7HA high efficiency air-cooled gas turbine is one of the industry leaders among advanced class gas turbine offerings and is available in three models—the 7HA.01 at 290 MW, the 7HA.02 at 384 MW, and the 7HA.03 at 430 MW.

| 7HA.01 | 7HA.02 | 7HA.03 | |

|---|---|---|---|

| Net output (MW) | |||

| Net heat rate (kJ/kWh, LHV) | |||

| Net efficiency (%, LHV) | |||

| Net heat rate (Btu/kWh, LHV) |

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%

The demands of today’s power generation industry are many: low cost of electricity, dispatch volatility, along with high efficiency, reliability, and asset availability. With approximately 950 installed units producing ~175GW of power in 11 countries, GE’s 7F.04 and 7F.05 gas turbines are proven performers in all these areas.

| 7F.04 | 7F.05 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

7F series gas turbines can balance renewables by load-following at 40 MW/min ramp rates while maintaining emissions compliance.

With unprecedented operational flexibility, robust engineering and long operation intervals, the GT13E2 can be used in many different applications—all while meeting a very broad range of environment and operating conditions.

| GT13E2-190 | GT13E2-210 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

GT13e2 gas turbines can run on up to 30% hydrogen fuel.

Formerly known as the Frame 9E, GE Vernova’s 9E gas turbine can help decrease costs and increase revenue for your plant. From the desert to the tropics to the arctic, the rugged 9E.03 heavy-duty gas turbine provides essential power and performs in a vast number of duty cycles and applications. The 9E.04 gas turbine provides increased power and performance while maintaining the simplicity and operational strengths of the 9E.03.

| 9E.03 | 9E.04 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9E series gas turbines can run on 52 types of fuel.

A single, economical solution for the dispatch needs of nearly every industry condition.

| LMS100 PA+ | LMS100 PB+ | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LMS100 gas turbines can start up in 8 minutes

The 7E.03 gas turbine is recognized as an industry leader for 60 Hz industrial power applications. Its robust architecture and operational flexibility make it well-suited for a variety of peaking, cyclic, and baseload operations. With state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path features, the 7E gas turbine can accommodate a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

| 7E.03 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

7E series gas turbines can deliver 100% load in 10 minutes.

GE Vernova’s 6F gas turbine offers the superior performance, reliability, and flexibility typically associated with larger power plants. Our 6F gas turbine packs big power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbine can maintain enhanced output and exhaust energy for combined cycle and CHP performance. The 6F offers segment-leading 32,000-hour combustion and hot gas path inspection intervals.

| 6F | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6F gas turbines offer fuel flexibility and hydrogen capability while maintaining the reliability you’ve come to depend on

A leader in the +40 MW space, the LM6000 has over 40 million operating hours and more than 1,300 units shipped.

| LM6000 PG | LM6000 PF | LM6000 PF+ | LM6000 PC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM6000 gas turbines can start up in 5 minutes

Its ability to operate in island mode, coupled with multiple decades of proven rugged performance, make the 6B an excellent solution for remote installations and extreme operating conditions. The rugged, reliable 6B heavy-duty gas turbine is a popular choice for refineries, natural gas liquefaction power, CHP applications, and industrial power.

| 6B | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6B gas turbines can operate on a wide range of non-standard gas or liquid fuels, including over 90% hydrogen

The LM2500 family of aeroderivative gas turbines boasts several times the operating experience of its competitors combined, and its flexibility and reliability are unsurpassed.

| LM2500XPRESS +G4 DLE | LM2500XPRESS +G5 DLE | LM2500 +G4 DLE | LM2500 +G4 SAC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM2500 gas turbines feature >99.8% availability

Introducing one of the world’s most modular, reliable, and experienced mobile gas turbines.

| TM2500 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

TM2500 gas turbines can be installed and commissioned in 11 days

Former name of GE 6F gas turbines: Frame 6C, Frame 6F, 6F.01, 6F 3-Series, 6F-3, 6FA.03, 6FA.01, 6FA, 6FA+e, 6F Syngas, 6111(FA), 6101(FA), PG6111FA, PG6101FA, MS6001(FA)

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more