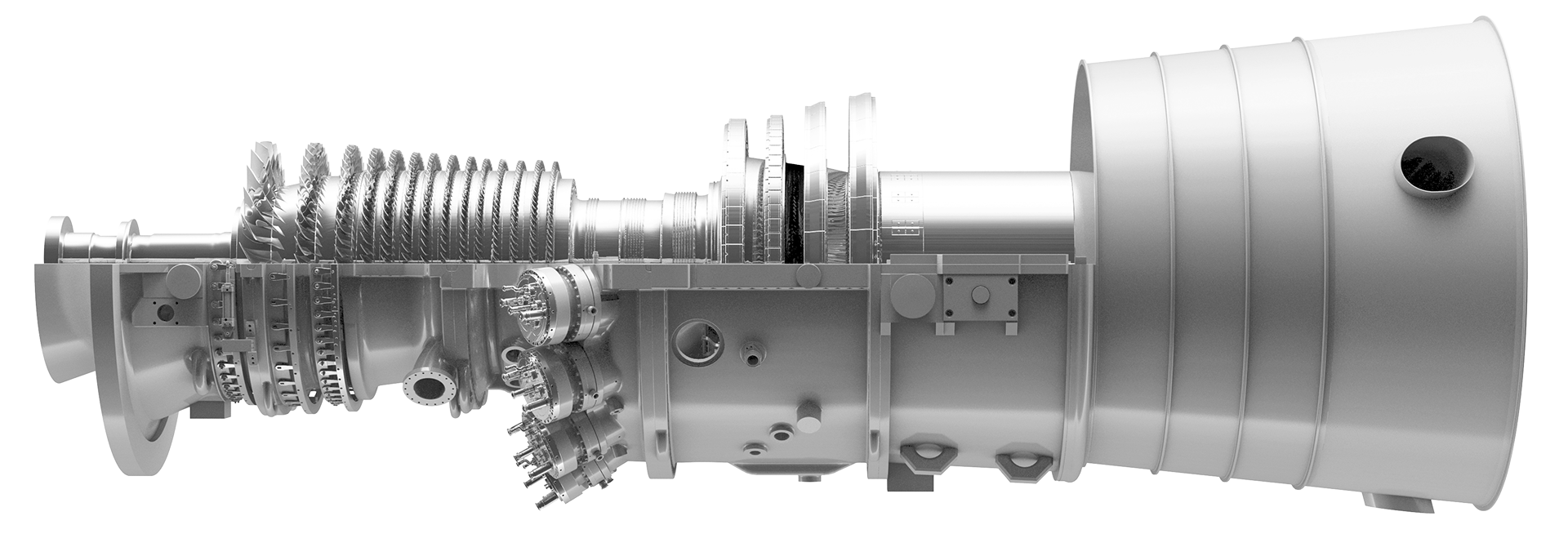

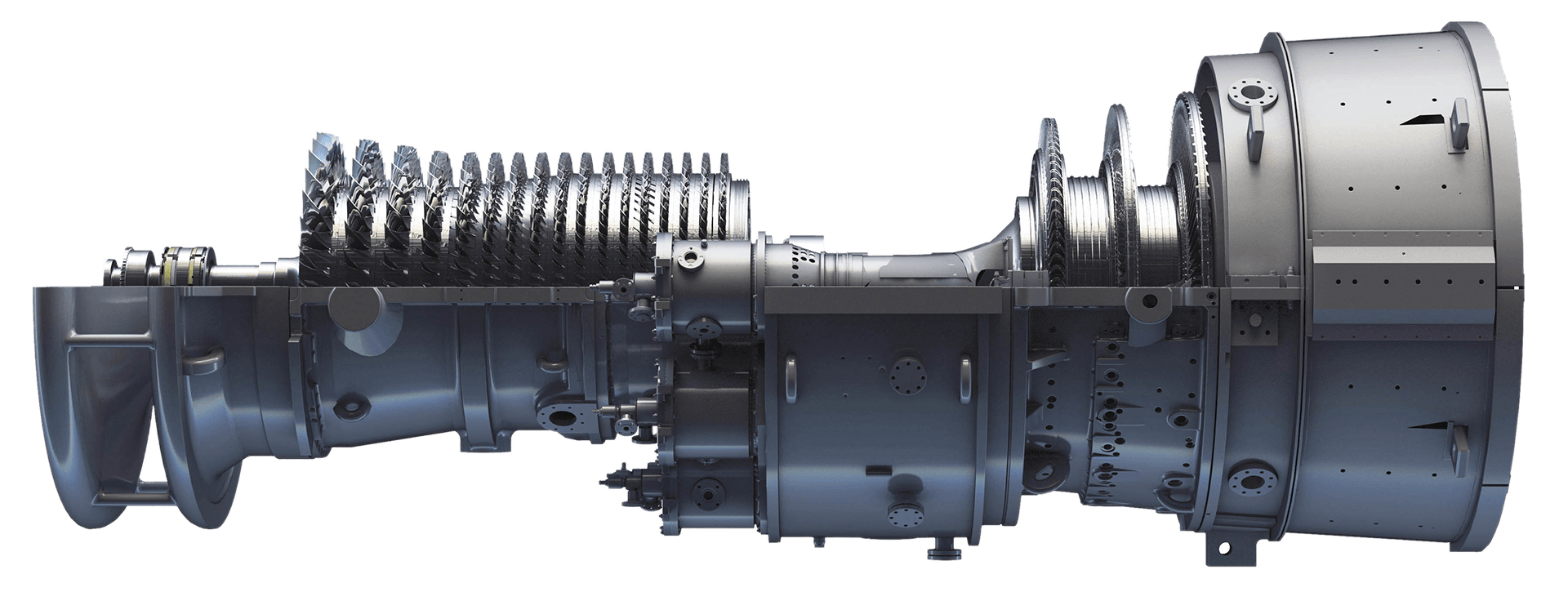

A pioneer in aeroderivative and heavy-duty gas turbine technology

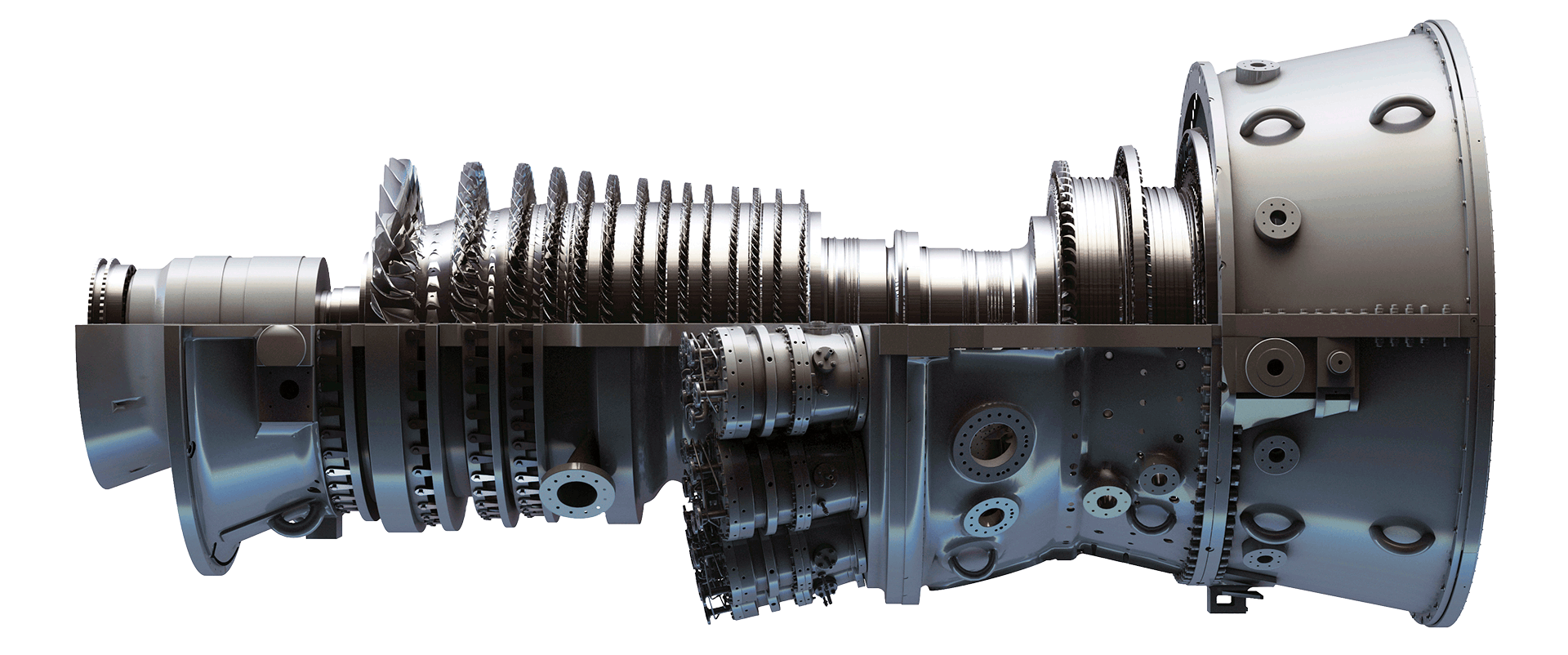

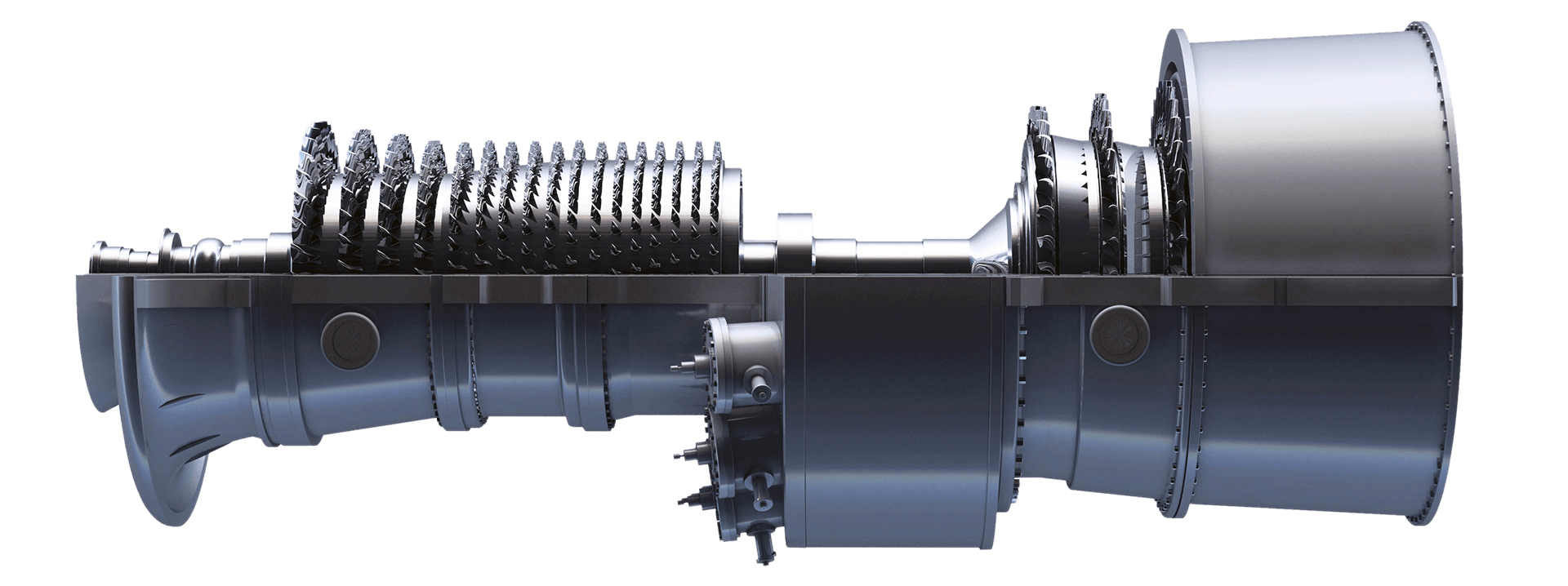

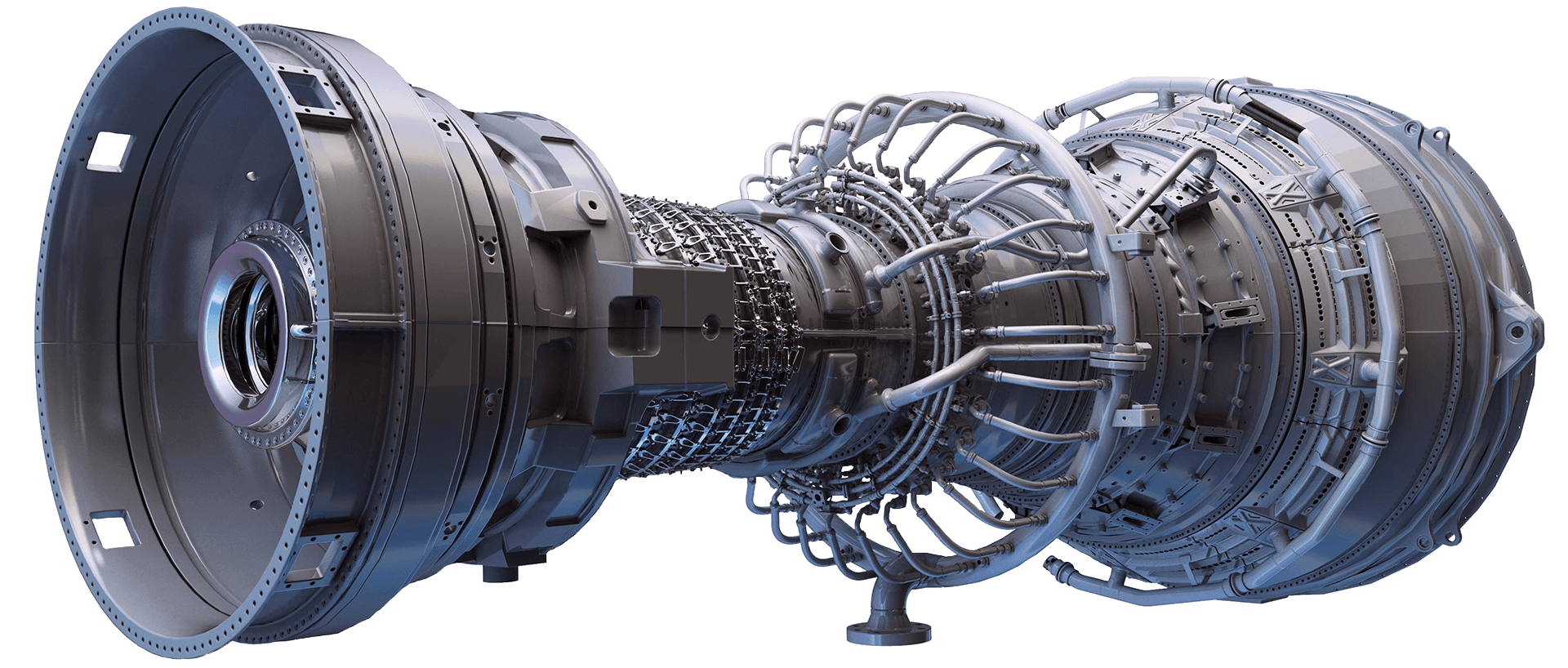

GE’s technology heritage is unparalleled in the power generation industry. Over the past 60 years, we’ve leveraged material science innovations from our aviation heritage to get increased performance at high firing temperatures. We were the first gas turbine manufacturer and supplier in the world to introduce single-crystal alloys, and we’ve devoted 15 years to developing ceramic matrix composites. As the industry leader in burning unconventional gas, GE introduced the first F-class gas turbine to use Arabian Super Light crude. In addition, we invented the Dry Low NOx (DLN) combustion system more than 30 years ago to reduce emissions—and it’s still being used today.

These advancements translate to both more power and more efficiency, which reduces lifecycle costs and enhances profitability for our customers. We continue to let innovation drive our company's product development, using a global exchange of knowledge, ideas, and tools—which we call the GE Store—to generate technology improvements and never-before-seen breakthroughs in gas turbine technology.