Strategic spare plant generator parts

Enhance reliability with spare gas generator parts

Generator parts to support your emergency response plan

Work together with GE to create the best spare gas generator part strategy for your installed generator assets. With planning, you can lower power plant generator downtime in case of major component failure and address any findings during planned inspections so that they can be fixed before the end of the outage. Strategic spares can be mutualized between identical assets.

Typical strategic spare generator parts include:

- Complete spare stator

- Stator bars

- Stator slot wedge material

- Coolers

- Terminal bushings

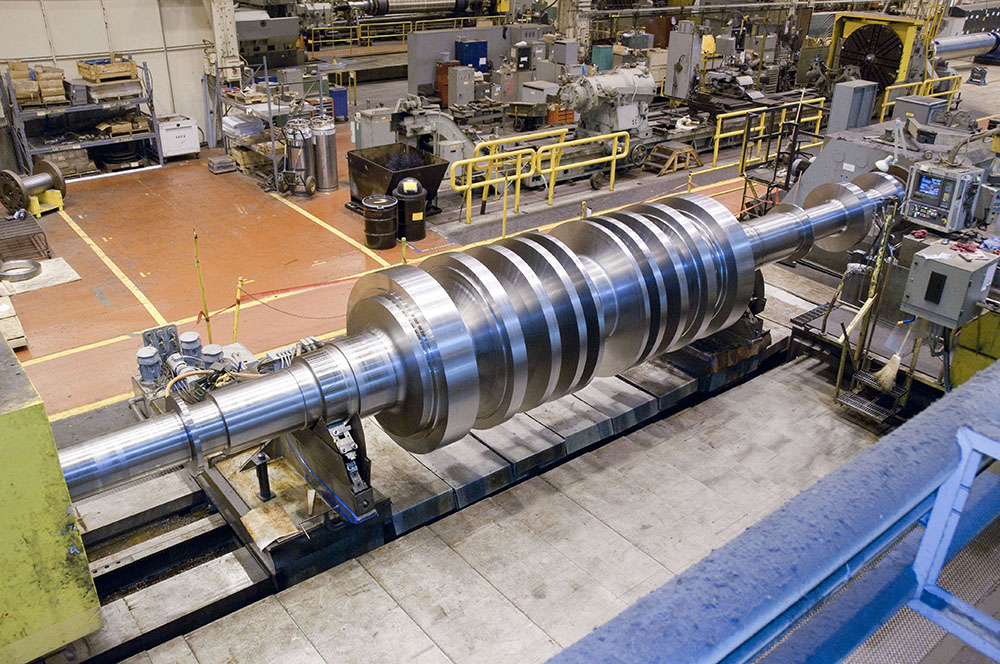

- Complete rotor

- Rotor coils

- Brushless exciter

- Balance of plant (i.e. replacement pumps)

Outage gas generator parts

Having the right power plant generator parts on hand before the beginning of an outage is vital for on-time execution. Your outage generator parts will have to support the open/close mechanical activities as well as the most common electrical repairs.

The parts needed to support open/close mechanical activities include:

- All screw locks, locking tabs and locking washers that maintain the generator tight in operation

- All filters that maintain the air, hydrogen or oil quality

- All seals, gaskets and compounds that have been broken to perform the inspection

- A set of coolers gaskets

- A set of bearing insulating material

- A set of bearing oil pipes or jacking oil pipes

- Any component in which the cost of access is higher than its cost

The parts needed to support the most common electrical repairs are:

- A set of diodes and fuses for the brushless exciter (when equipped)

- A set of carbon brushes in case of static excitation

- A set of grounding brushes or braids

- Electrical solvents, ties, resin and electrical paint matching your winding to locally repair your generator winding

Larger upgrades

Explore our additional parts upgrades

Technology-driven gas generator auxiliary systems upgrades

Auxiliary systems upgrades can provide full compliance with today’s safety regulations for power plant generators.

From generator assessments to identifying generator upgrade potentials, through partial modernizations, to replacements of complete systems, we address parts obsolescence, safety regulations, redundancy, or reliability requirements.

Tilt Pad Bearing for 7FH2

This retrofit kit is engineered to prevent reoccurrence of edge wear and desensitize the bearing to causes of misalignment such as foundation settling, thermal distortion, and cold-to-hot-to-cold growth mismatch, which could lead to elevated bearing metal temperatures and bearing damage in generators.

Hydrogen seal ring

The improved hydrogen seal ring is engineered with a mechanical stop to limit seal ring movement during transient seal oil pressures and restore normal oil flow path more efficiently, reducing the risk of significant seal oil ingress into the generator.

Generator collector brush holder

Newly engineered to improve the ease of brush and spring replacement, the enhanced generator collector brush holder increases brush life, decreases the time required for brush change-out, and reduces the risk of collector flashovers.

Generator flexibilization package

If your plant was engineered for base load and is now load cycling, supplying reactive power or starting and stopping, the reliability of your generator can be increased by implementing a generator flexibilization package.