Regulation compliant

A full suite of wet and dry solutions

Our portfolio of wet and dry FGD services and know-how is at your disposal. We can innovate for your particular needs, finding the right balance of cost-effectiveness and efficiency for your FGD system.

Tailored for regulations

Strict environmental regulation requires improved solutions for flue gases. GE is committed to finding innovative solutions to existing FGD systems with upgrades for increased performance and energy savings. As every FGD system is unique, GE takes a tailored approach to determining the FGD service solutions you need.

FGD upgrade options include:

- Spray headers for improved design for uniform flue gas coverage

- Nozzle types for optimal droplet diameter and dispersion

- Mist eliminators to prevent droplets carryover at reduced pressure loss

- Performance enhancing plates to increase gas-to-liquid contact

- Tray upgrades for optimal velocity with additional perforated tray

- Slurry preparation equipment of ball mills, mixers, and pumps

Reduce wet FGD power consumption and mercury re-emission

Our patented new SulfiTrac* sulfite analyzer is the first online solution for continuous improvement of energy consumption while reducing mercury emissions. This is accomplished by measuring and controlling the sulfite ion concentrations within the wet flue gas desulfurization (WFGD) slurry.

With GE’s sulfite analyzer hardware and software, you can reduce the power consumption of the oxidation air blowers by injecting only as much air as needed while maintaining gypsum purity. Configured to cope with harsh environments in heavy industrial applications, the sulfite analyzer is suitable for most power plants or industrial processes with a WFGD.

Wet FGD upgrade benefits include:

- Reduces FGD power consumption and costs

- Improves air input rate according to boiler load and coal sulfur conditions

- Reduces mercury re-emissions and dissolved mercury in WFGD purge stream

- Eliminates the need for chemical additives for mercury reemissions control

- Prevents sulfite blinding and maintains high gypsum quality

- Improves manganese solubility to reduce corrosion potential Maintains proper speciation of selenium in WFGD purge stream.

*Today GE's AQCS offerings are limited to the USA, Canada, India, Bangladesh, and Sri Lanka.

Advanced mercury control technology

GE has developed an advanced, patented mercury control technology capable of high removal efficiencies for wet and dry FGD systems. Mer-Cure* is an enhanced activated carbon injection system with unique attributes that improve mercury oxidation and subsequent mercury capture. The sorbent is injected into the duct upstream of the air heater, allowing enhanced use of the effective temperature range for oxidation and providing longer residence time for improved mercury capture.

For additional mercury capture and reduced sorbent consumption, our patented activated carbon milling technology can add even greater mercury capture and reduced sorbent consumption.

Benefits for FGD systems include:

- Enhanced mercury capture by up to 90%

- Reduced sorbent consumption by up to 50%

- Lowered OpEx

- Wider range of potential sorbent suppliers

The advantages of improved design

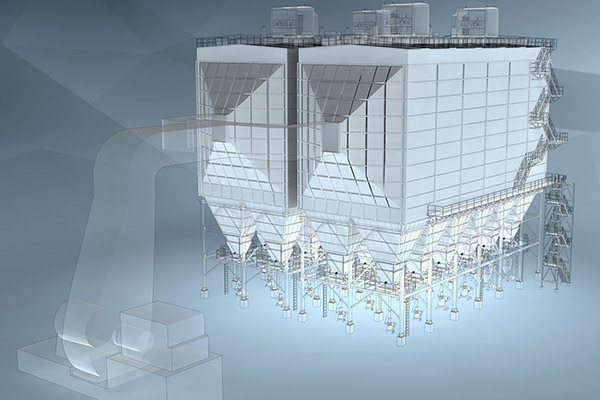

Wet FGD systems

Wet FGD spray headers

The optimal alignment and distance between the wet FGD spray headers and the nozzles enable a uniform distribution of the liquid (slurry) and the flue gas. GE’s design increases the gas/liquid contact and improves the SO2 removal efficiency at lower energy consumption.

Wet FGD nozzle types: Ideal droplet dispersion

GE increases the efficiency of the SO2 absorption with the right design and location on the spray bank of the spray nozzles. Our hollow cone and bi-directional nozzles are positioned with computer modeling to achieve the best possible gas to liquid contact, scrubbing efficiency, and reduced gas sneakage.

Wet FGD mist eliminator: Prevents carryover at reduced pressure loss

GE’s modeling of the mist eliminators, spacing and orientation reduces the droplet re-entrainment. Through extensive testing and experience, GE recommends the appropriate washing cycle that secures low pressure drop translating in energy savings and securing reliable operation.

Contact us

Want to learn more about our FGD services and upgrades?

*Today GE's AQCS offerings are limited to the USA, Canada, India, Bangladesh, and Sri Lanka.