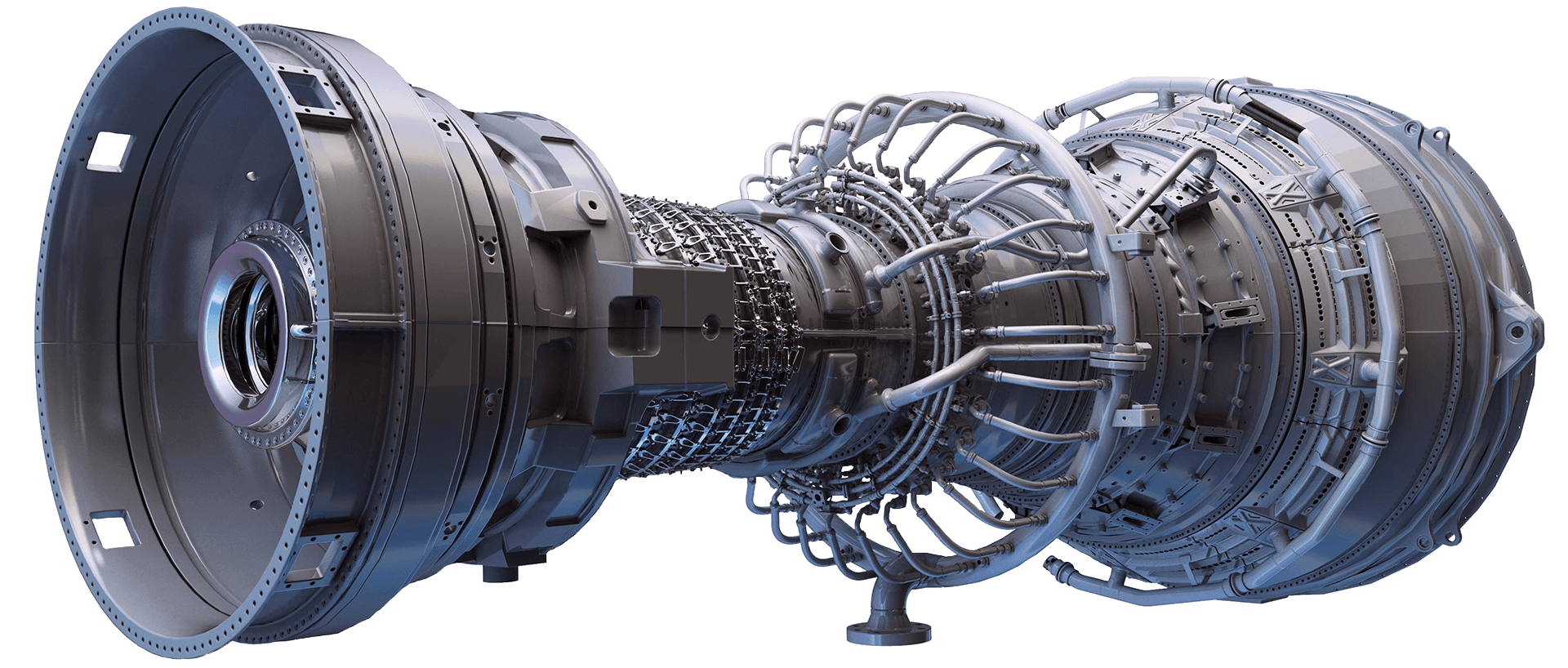

Welcome to tomorrow's energy—today

Access to affordable, reliable, flexible, and sustainable power is fundamental to modern life. As the world is shifting towards a lower carbon future and exploring solutions like hydrogen and carbon capture and sequestration, GE Vernova is ready to be your partner in leveraging the role of natural gas for powering the world today and tomorrow.