Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

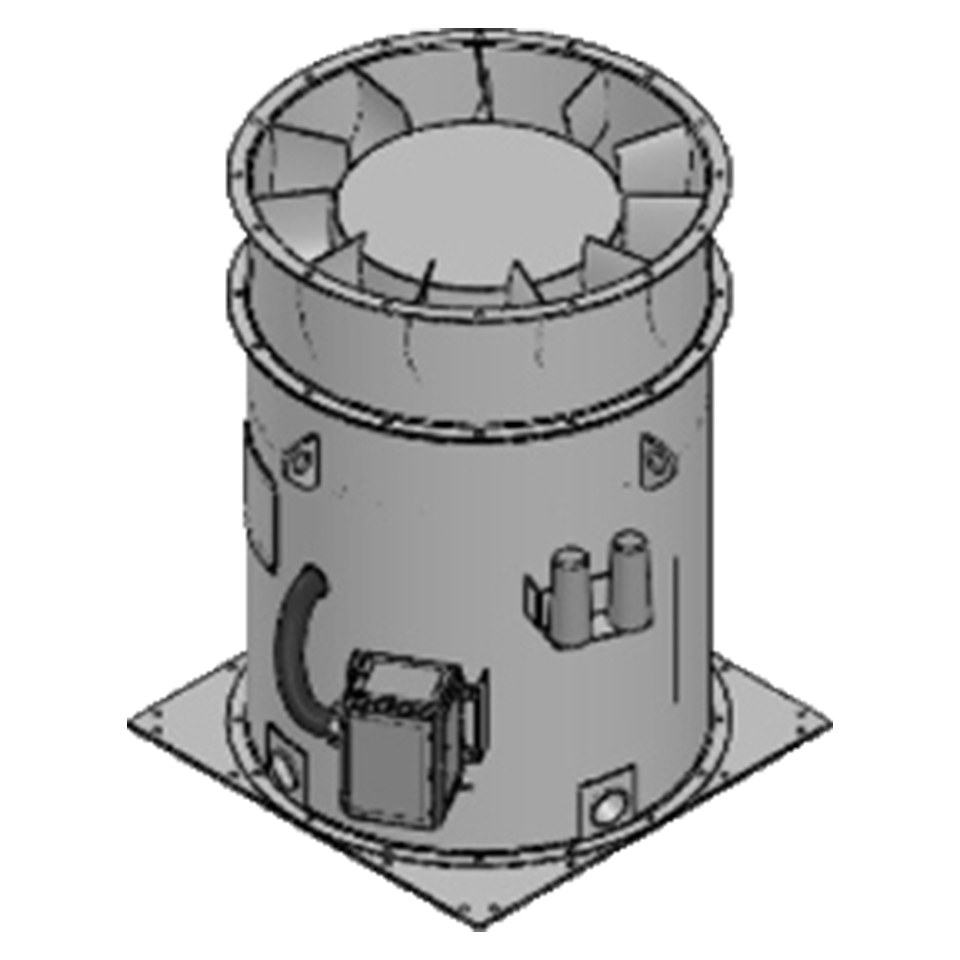

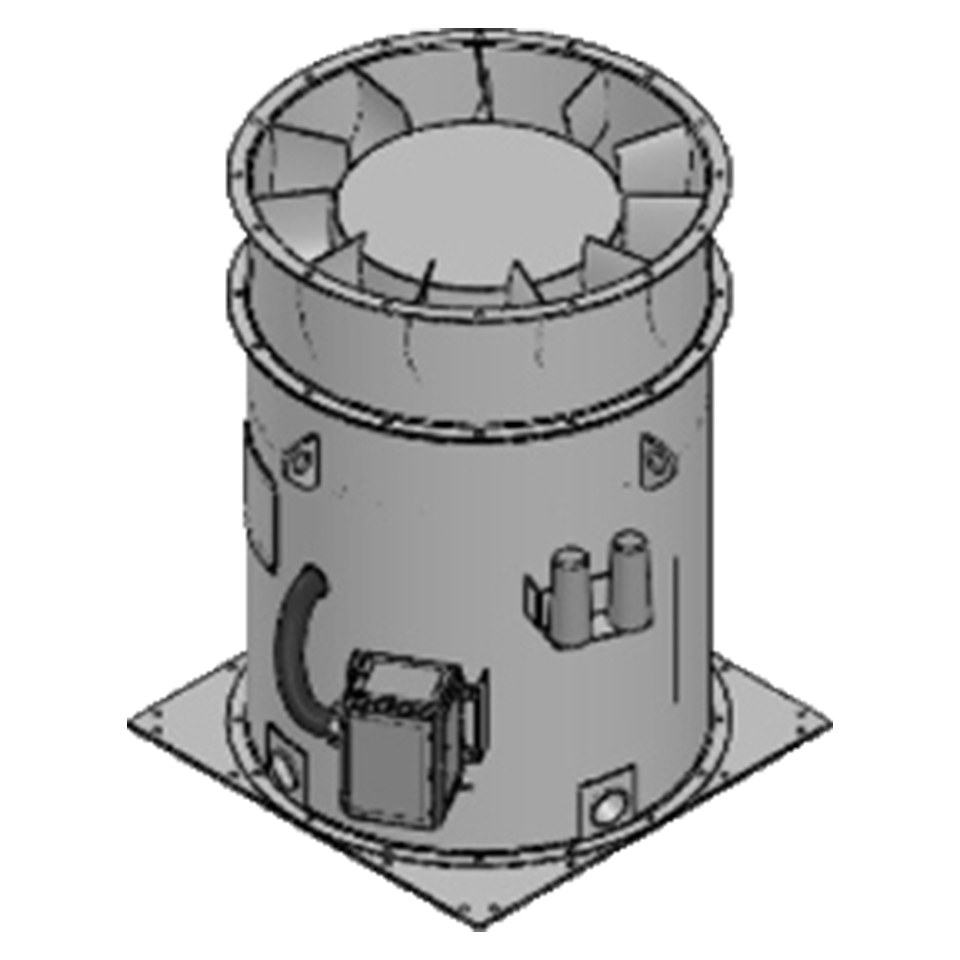

Direct drive ventilation fan upgrade

GE’s direct drive ventilation fans eliminate belts and tensioning maintenance, which can cause over-tensioning, overloaded bearings, and fan failure.

Benefits

What can upgrading do for you?

These direct drive fans are designed to replace your current fans with limited disruption. They’re are a drop-in upgrade for belt-driven fans for GE packages and can:

- Eliminate the squealing belts on startup and the process of properly tensioning the drive belts.

- Eliminate maintenance and replacement of fan belts.

- Eliminate startup noise from belts slipping.

- Eliminate pillow block bearings and their maintenance.

- Feature external grease ports for quick and easy access (auto-lube kit optional).

- Provide improvement in generator enclosure pressure, lessening generator oil-leak potential, and differential pressure-alarm activation.

How we get you there

- The existing belt-driven fans have been redesigned to eliminate the drive belts by moving the fan motor inside of the fan assembly, directly connected to the fan blade shaft.

- Grease fittings are located outside of the fan assembly for easy access when lubricating the fan shaft bearings and the motor bearings.

- Air vents were added to the fan casing to utilize ambient air to maintain adequate motor cooling.

Reused equipment

- Existing damper and duct flex

- Existing electrical cables at the new motor junction box

- Existing silencer and hoods

Download our direct drive fans fact sheet

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.