Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

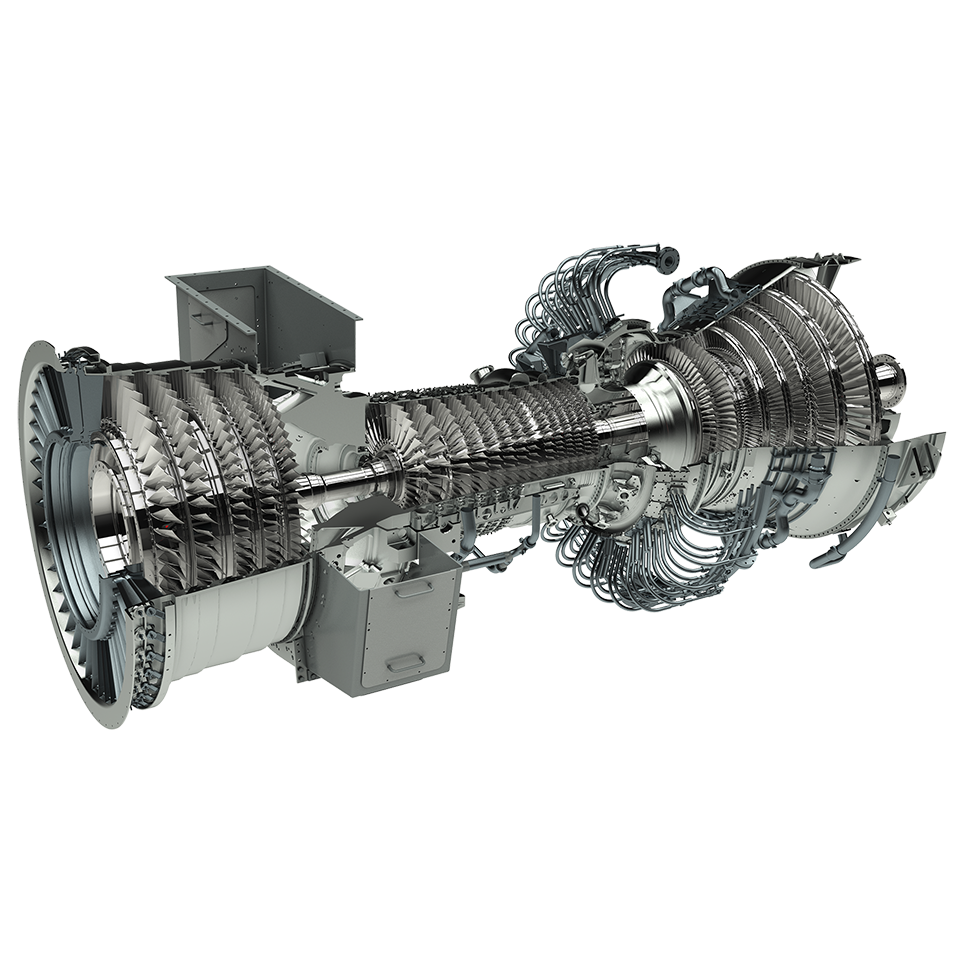

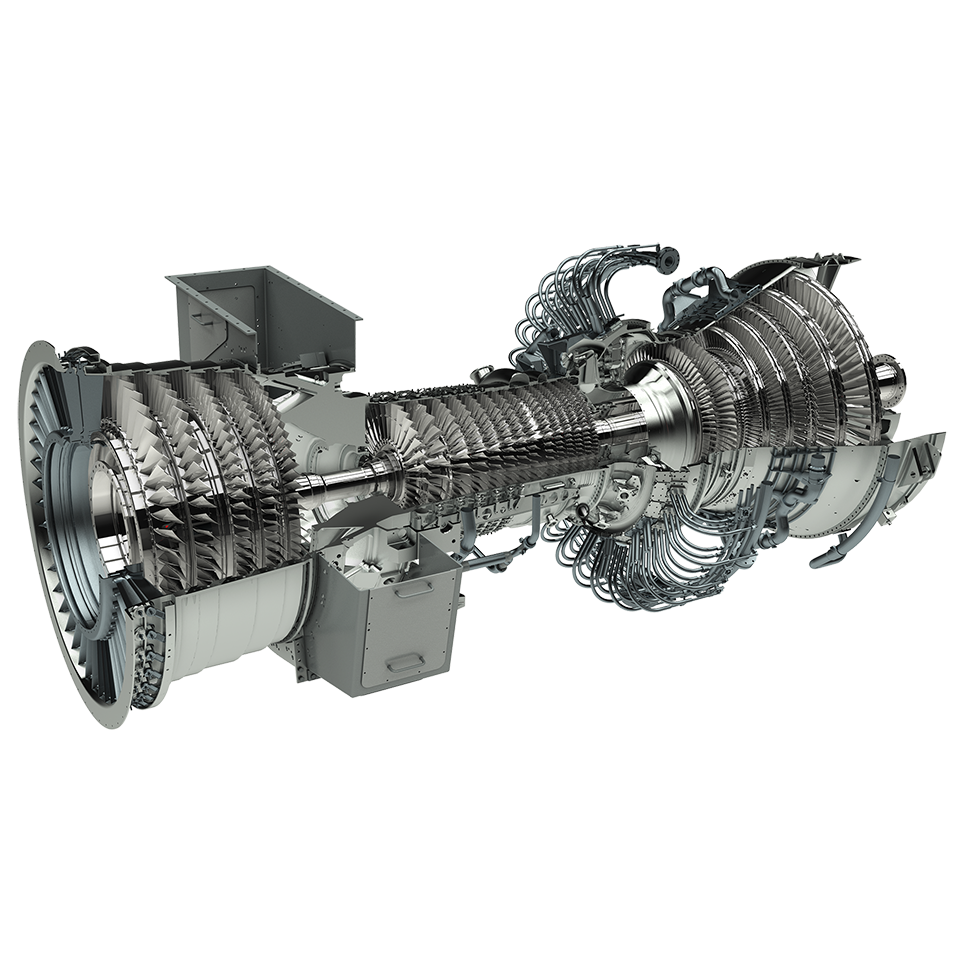

Gas to dual fuel—LM6000

With GE’s gas to dual-fuel upgrade, your LM6000 turbine can run on either gas or liquid fuel, with or without water injection for NOx control.

Benefits

What can upgrading do for you?

The modification includes the addition of dual-fuel manifolds with water injection capability, dual-fuel nozzles, metering valves, shutoff valves, liquid fuel boost skid, and control system updates as needed.

- Improved versatility of the package by allowing the LM6000 turbine to operate on either liquid fuel or natural gas.

- Availability of the package can be maintained in the event of a disruption to natural gas fuel supply.

- Increased operational flexibility—and profitability—introduced with the capability to switch from one fuel to another, even at full load. CDP air-cooling system is required for full load transfers.

How we get you there

- The upgrade includes on-engine, off-engine, and the off-package liquid fuel delivery and filtration skids, along with updated controls software and hardware, to yield a unit capable of operating on either natural gas or liquid fuel.

- Main mechanical changes consist of installing all major components and piping to supply liquid fuel from the customer connection (flanged outside of main base) to the on-engine liquid fuel manifold.

- Standard package components consist of a fuel-metering valve, shutoff valves, check valves, and fuel return lines.

- New liquid fuel manifolds and fuel nozzle tubes are installed on the turbine and the gas fuel nozzles are replaced with dual-fuel nozzles.

- A gas purge system and a compressor discharge pressure (CDP) purge system is also installed.

- Gas fuel is used to purge the liquid fuel system while operating on gas fuel to prevent backflow from the combustor.

- CDP air is used to purge the gas-fuel system during liquid fuel operation to prevent coking of the gas fuel circuit and backflow from the combustor.

- 50Hz and 60Hz can be selected, adding applicable 50Hz and 60Hz parts and maintaining common parts to both systems. A CDP cooler can be selected for both 50Hz and 60Hz options.

- Customers already configured for water injection must replace the water injection pumps with high-pressure pumps to properly operate on liquid fuel and meet 42 ppm NOx.

- An optional CDP cooler can be added to allow fuel transfers at full load.

- Optional liquid fuel forwarding and boost pump skids are available separately.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.