Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

LM6000PC SAC extended life combustor upgrade

LM6000PC SAC extended life combustor features redesigned primary and secondary swirlers to alleviate issues with anti-rotation tabs and coating loss, extending the life of both the combustor and downstream components.

Fast facts

Applicable turbine models:

Time to install

7-20+ days

Inspection type

Medium

(if done as exchange)

Major

(if sent to service center)

Benefits

Extended combustor life

This upgrade additionally implements improvements from the new rich quench mix (RQM) engineering utilizing enhanced combustor liners that improve dilution characteristics (repositioning of combustion location and lowering combustion area), enabling lower emissions than rad-rad combustors by using less water.

What can upgrading do for you?

Replace jet-rad with rad-rad swirlers:

- Improved aerodynamics

- Reduced NOx water erosion

- Reduced floating mass

Dual skin venturi:

- Reduce thermal stress

- Eliminate flash boiling

- Reduce thermal gradient across thermal barrier coating (TBC) and base metal

T800 coated floating ferrule:

- Reduce bore wear

- Requires fuel nozzles with T800 wear coating and reworked flange (new bold lengths required for reworked flange)

RQM upgrade from rad-rad combustor (G48):

- Redesigned combustor liners improve dilution characteristics by repositioning combustion location, lowering combustion area for lower emissions

Extended life combustor

Full range of benefits

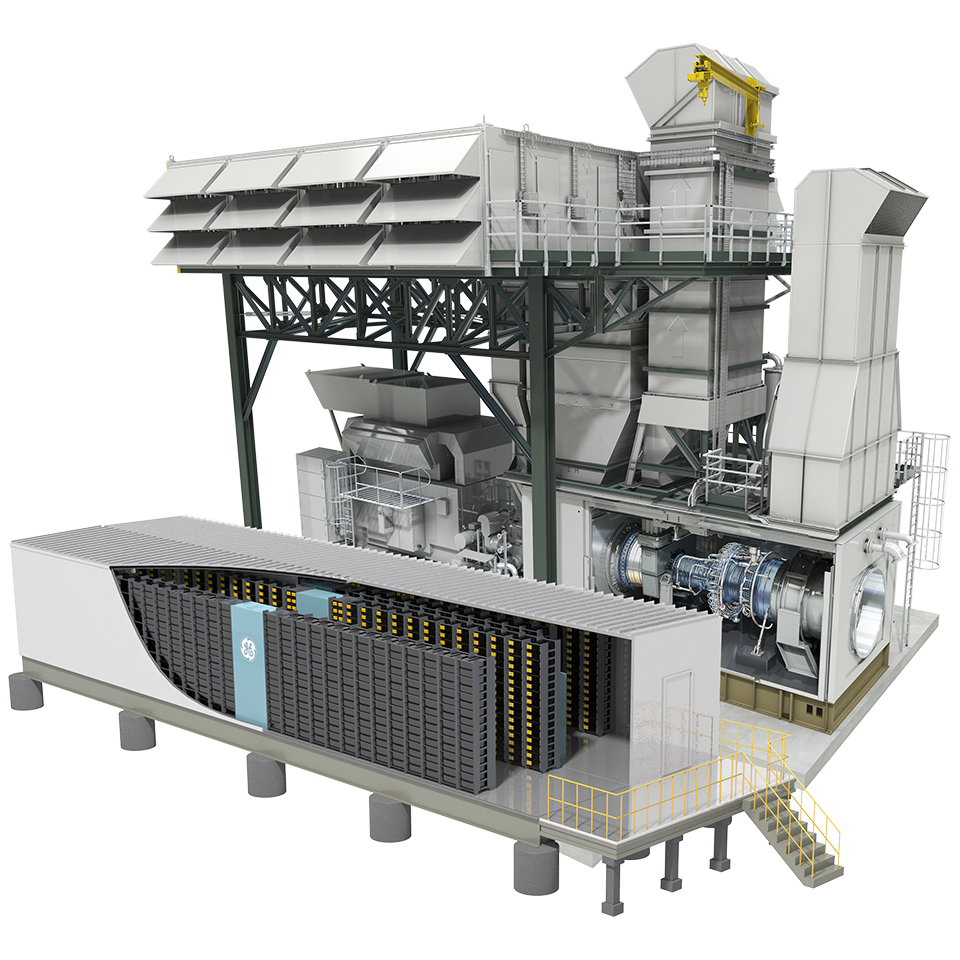

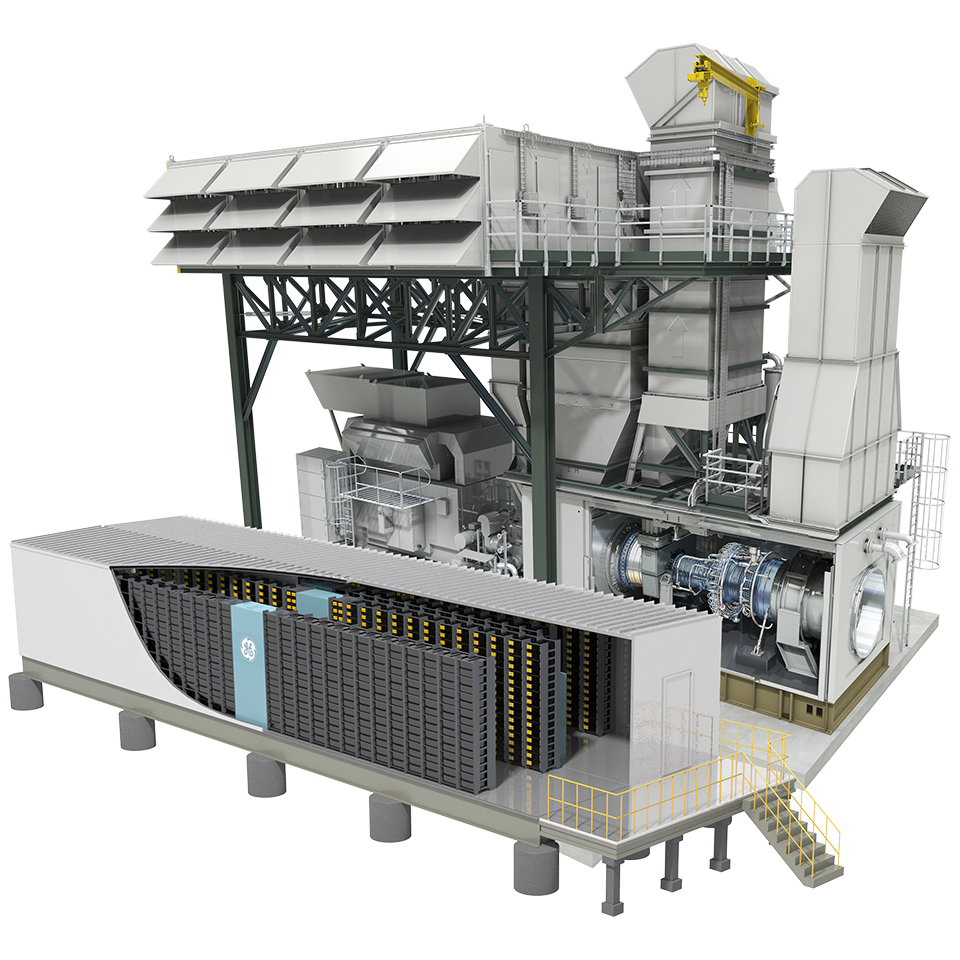

- The LM6000PC SAC extended life combustor upgrade includes utilizing the swirler configuration from the LM6000PG product to increase life by improving the swirlers, venturis, and coatings along with improved swirler aerodynamics.

- The primary jet-rad swirlers are replaced with a rad-rad swirler configuration. The rad-rad configuration significantly reduces the possibility of cracking occasionally found in the jet-rad primary swirler and the secondary swirler resulting from environmental attack and thermal stresses from NOx water. The floating mass of the swirler was reduced and the anti-rotation tabs were eliminated to improve life.

- The venturis were also upgraded to a dual-skin help reduce thermal stresses and eliminate flash boiling inside of the venturi. It also reduces the thermal gradient across the thermal barrier coating (TBC) and base metal significantly, improving the life of the coating.

- Lastly, the coatings on the fuel nozzle tip and the floating ferrule bore were changed to a T800 wear material to significantly reduce bore wear. The T800 wear coating is a cobalt-chromium-molybdenum coating designed to significantly reduce wear between the nozzle tip bore and fuel nozzle tip.

- The combustor upgrade can include upgrades from jet-rad to rad-rad only, or from jet-rad to rad-rad/RQM, which includes benefits of the rad-rad design plus the benefits of the RQM engineering (NOTE: an increase in CO emissions could be expected).

Contact us

Contact us for a quote on the LM6000PC SAC extended life combustor upgrade.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more