As the world’s largest manufacturer and supplier of gas turbine technology, GE offers a wide array of equipment options and models to meet your most challenging energy requirements. Discover the best solution to balance your global energy goals and your budget.

Search GE Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

Products

Find the right gas turbine to meet your needs

Whether you're generating power for entire cities, electrifying your own operations, or are facing an emergency electricity shortage and need power fast, we can act as a versatile gas turbine supplier, ready to quickly provide a range of solutions.

- 50Hz

- 60Hz

- Simple

- 1x1CC

- 2x1CC

- All

- Heavy duty

- Aeroderivative

9HA

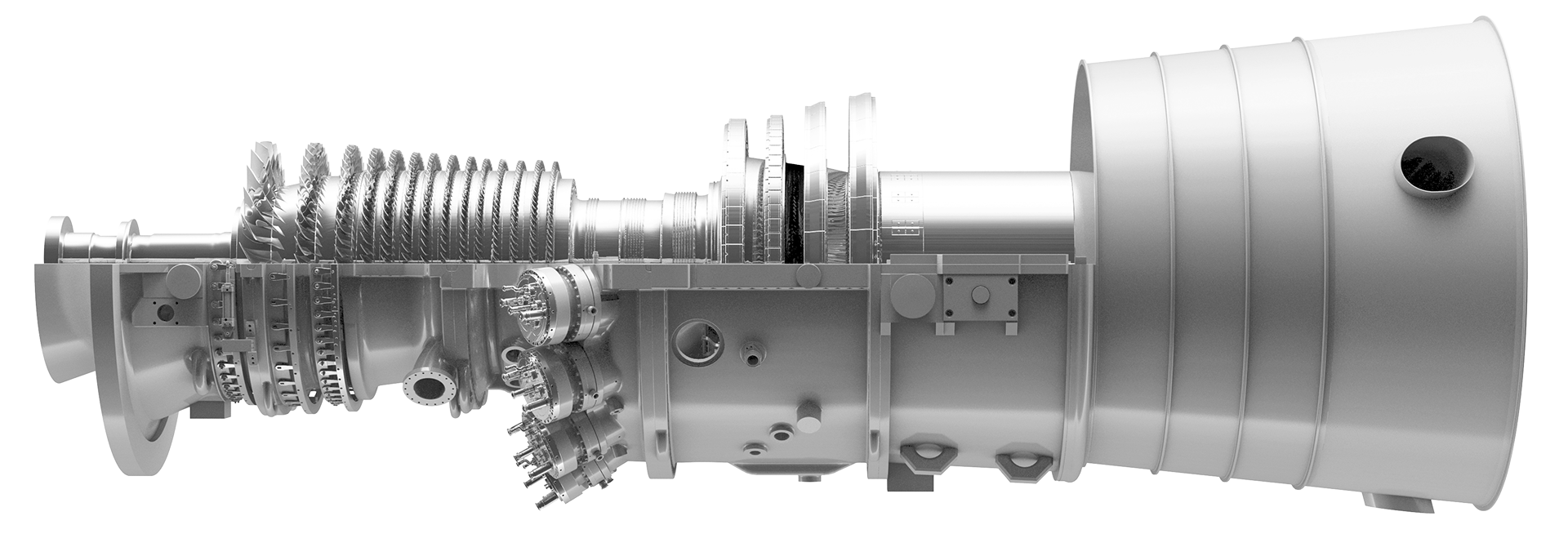

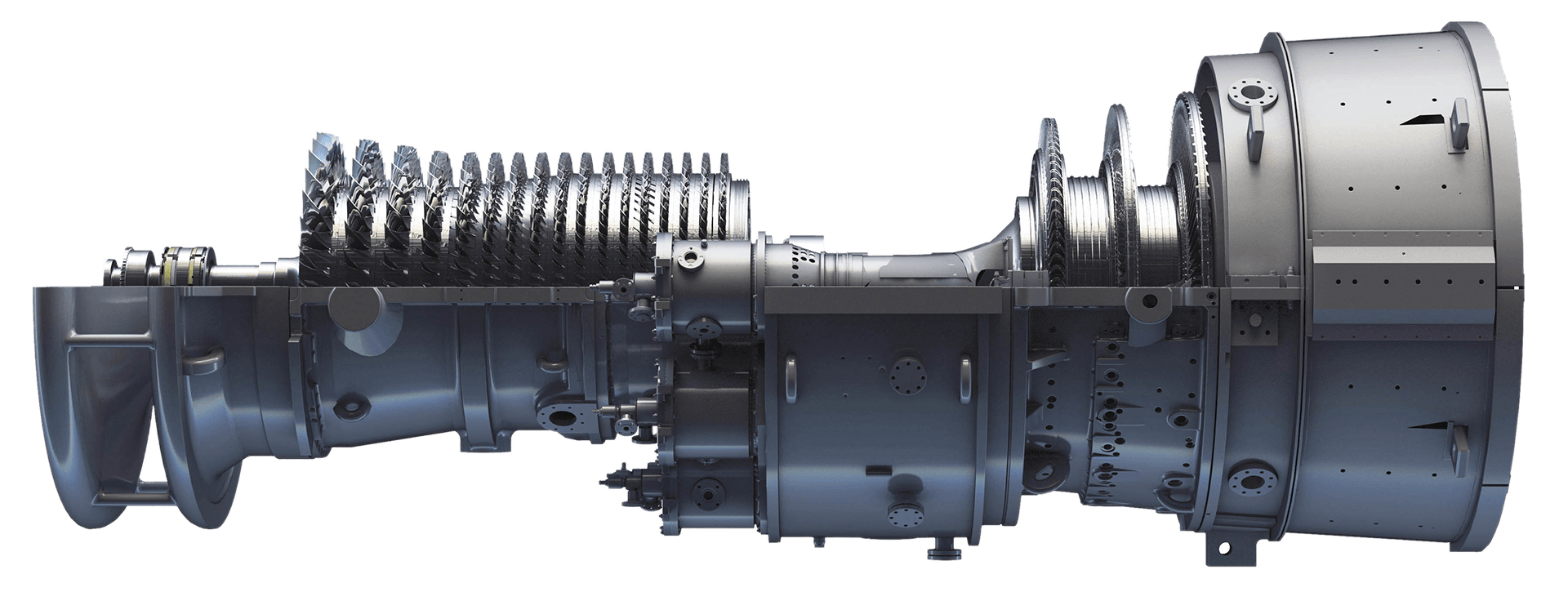

GE Vernova’s 9HA high efficiency, air-cooled gas turbine is one of the industry leaders among H-class offerings, and now the 9HA gas turbine is at the heart of the world's most efficient combined-cycle power plant.

| 9HA.01 | 9HA.02 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9HA gas turbines are 50% hydrogen (H2) capable with a technology pathway to 100%

9F

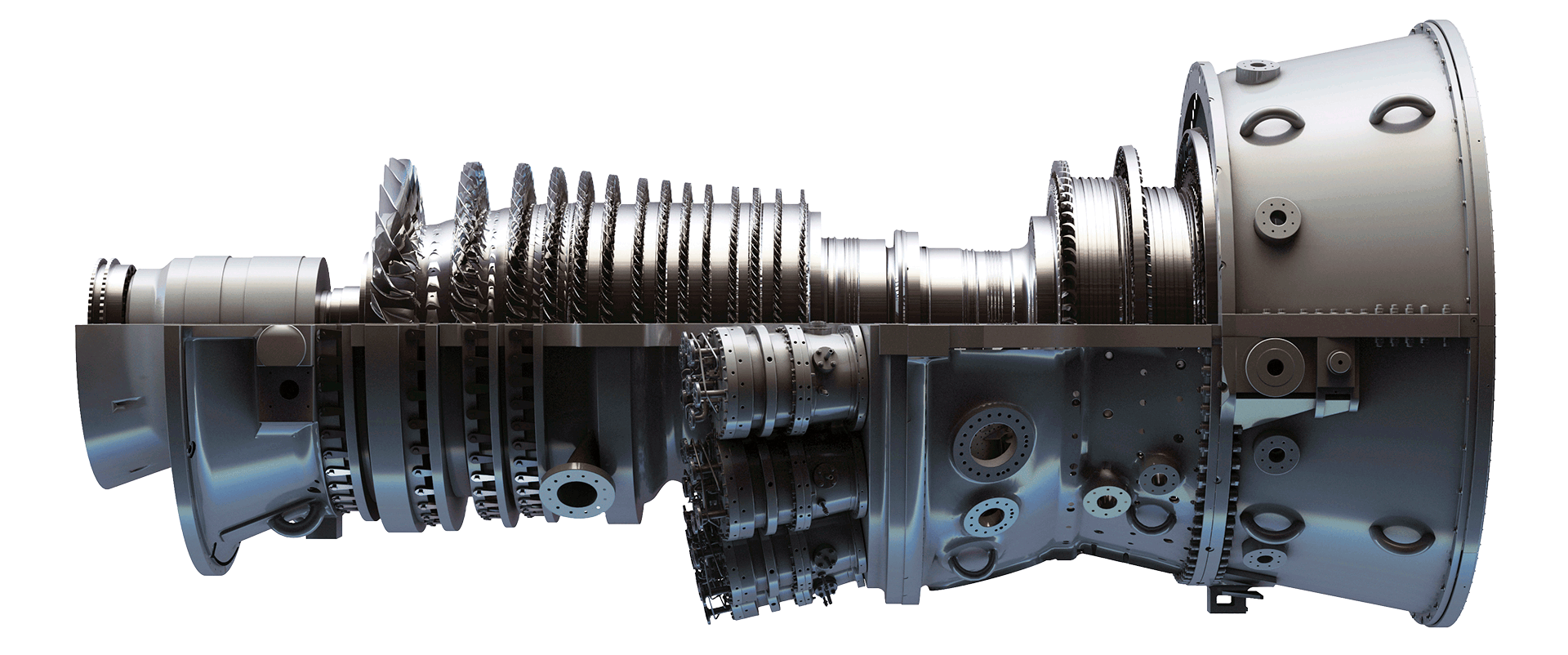

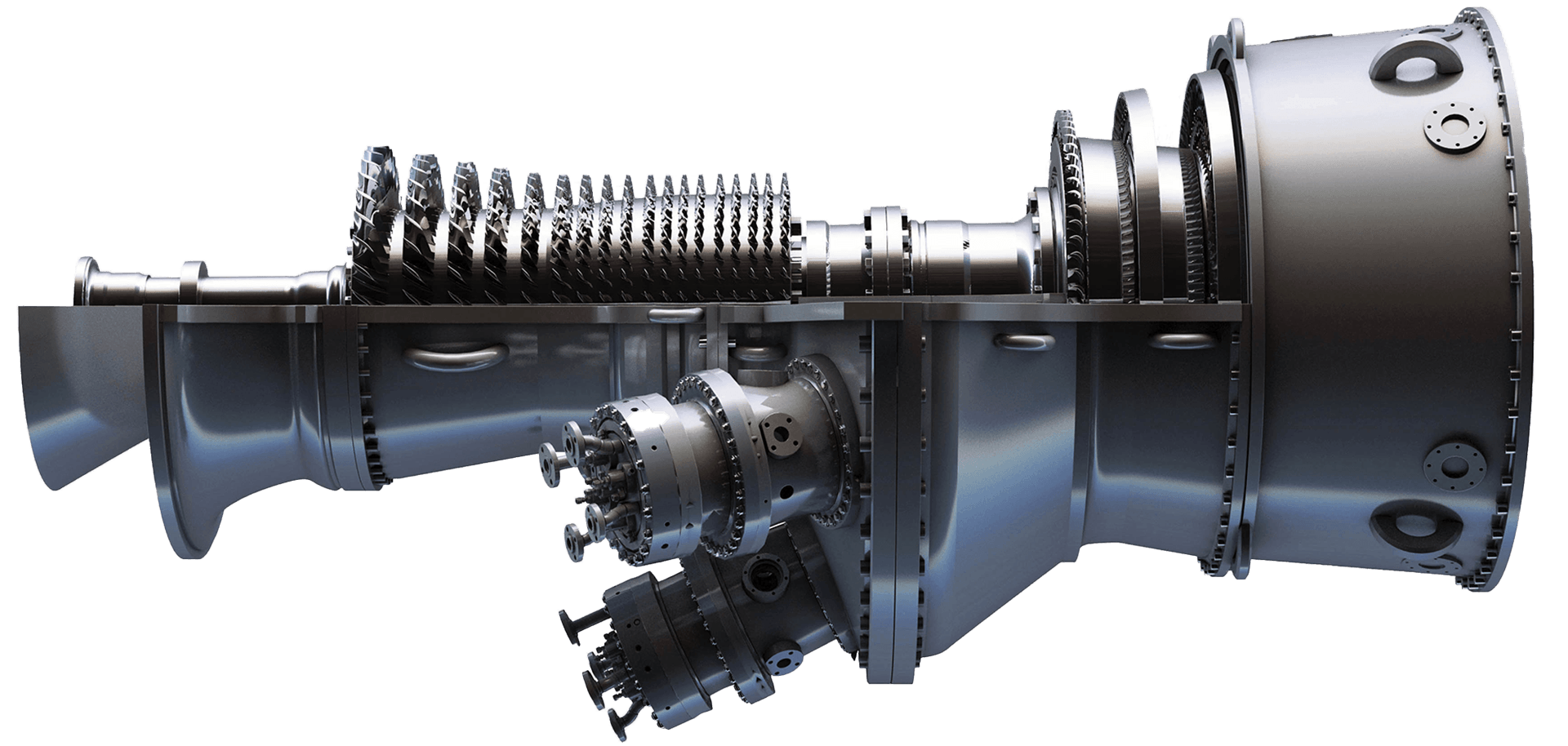

With over 450 units deployed to more than 40 countries, GE Vernova has the largest operating and most experienced OEM F-class fleet in the world. Our 9F gas turbine delivers consistent performance and accommodates a diverse range of fuels, making it great for a variety of combined cycle and CHP applications.

| 9F.04 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

9F series turbines are GE’s most advanced F-class technology for 50 Hz applications.

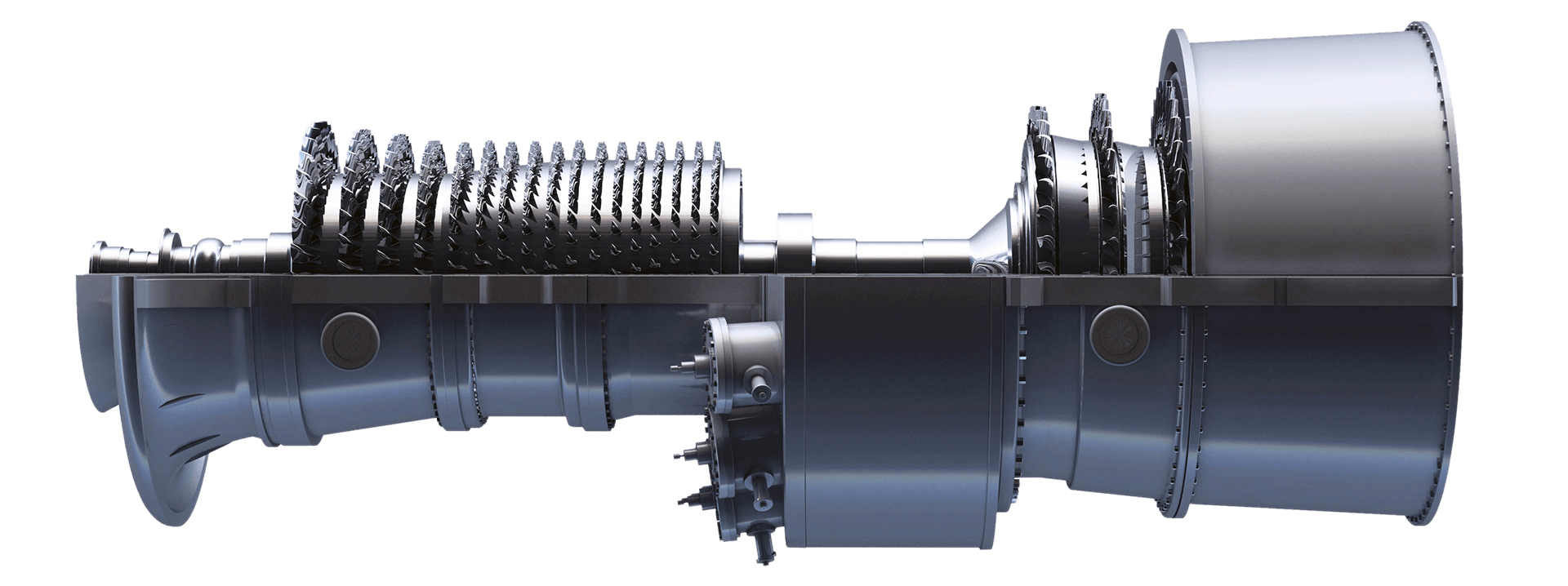

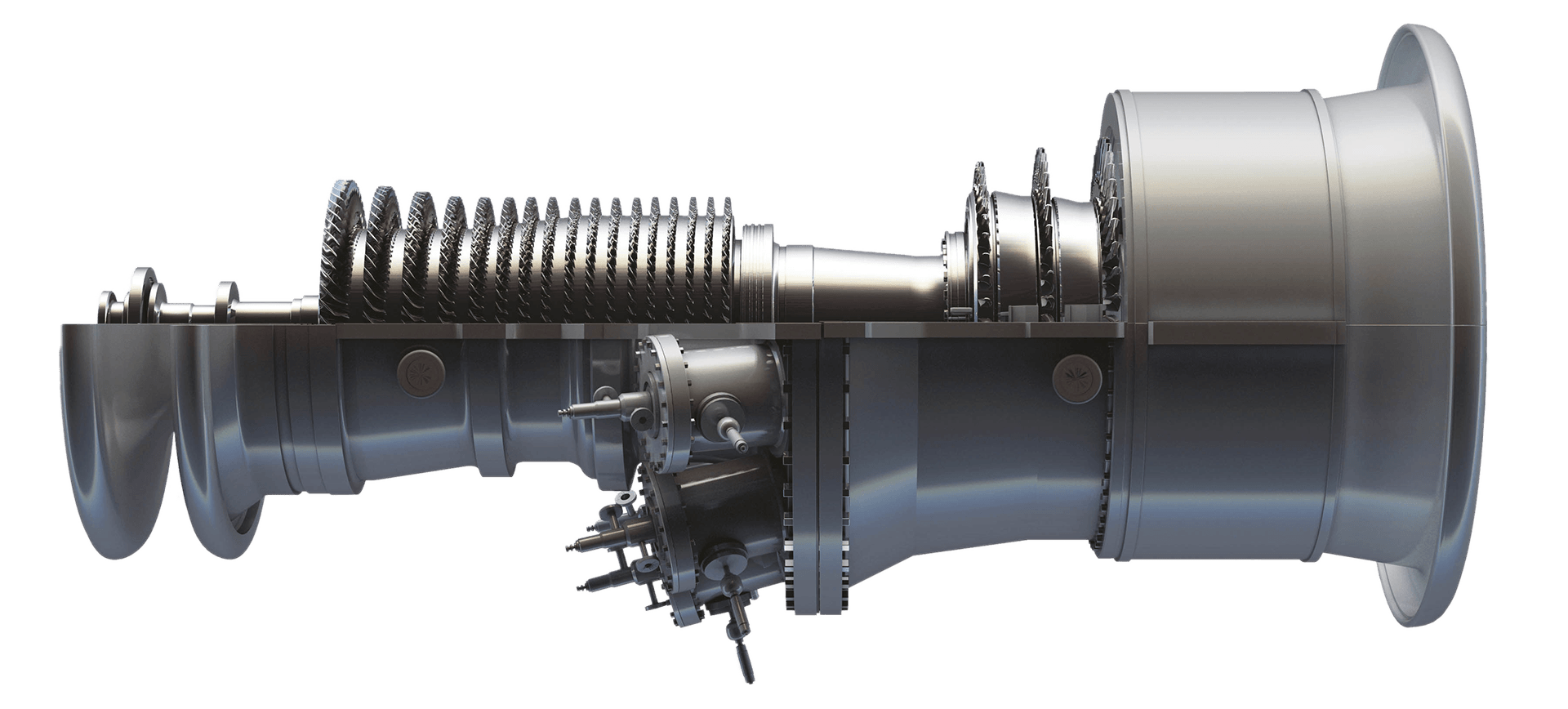

7HA

GE’s 7HA high efficiency air-cooled gas turbine is one of the industry leaders among advanced class gas turbine offerings and is available in three models—the 7HA.01 at 290 MW, the 7HA.02 at 384 MW, and the 7HA.03 at 430 MW.

| 7HA.01 | 7HA.02 | 7HA.03 | |

|---|---|---|---|

| Net output (MW) | |||

| Net heat rate (kJ/kWh, LHV) | |||

| Net efficiency (%, LHV) | |||

| Net heat rate (Btu/kWh, LHV) |

7HA gas turbines are up to 50% hydrogen (H2) capable with a technology pathway to 100%

7F

The demands of today’s power generation industry are many: low cost of electricity, dispatch volatility, along with high efficiency, reliability, and asset availability. With approximately 950 installed units producing ~175GW of power in 11 countries, GE’s 7F.04 and 7F.05 gas turbines are proven performers in all these areas.

| 7F.04 | 7F.05 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

7F series gas turbines can balance renewables by load-following at 40 MW/min ramp rates while maintaining emissions compliance.

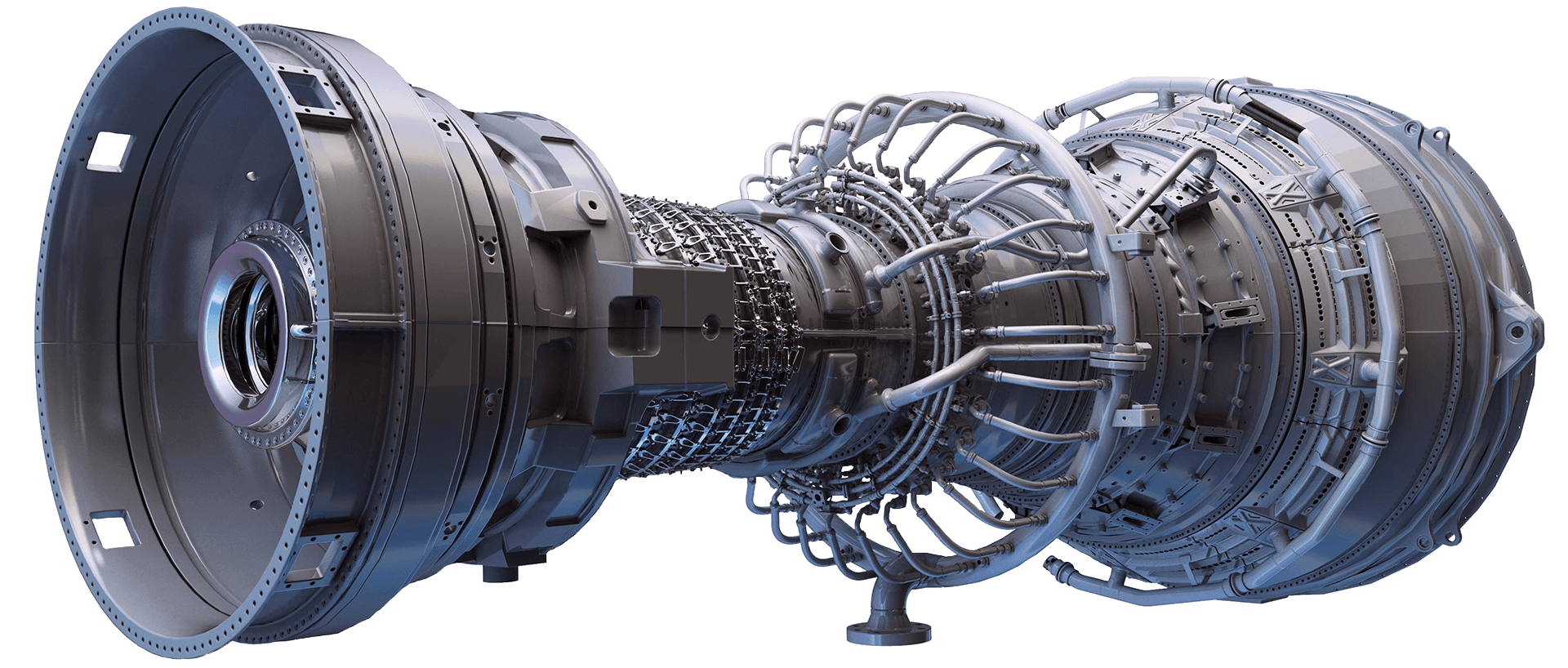

GT13E2

With unprecedented operational flexibility, robust engineering and long operation intervals, the GT13E2 can be used in many different applications—all while meeting a very broad range of environment and operating conditions.

| GT13E2-190 | GT13E2-210 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

GT13e2 gas turbines can run on up to 30% hydrogen fuel.

9E

Formerly known as the Frame 9E, GE Vernova’s 9E gas turbine can help decrease costs and increase revenue for your plant. From the desert to the tropics to the arctic, the rugged 9E.03 heavy-duty gas turbine provides essential power and performs in a vast number of duty cycles and applications. The 9E.04 gas turbine provides increased power and performance while maintaining the simplicity and operational strengths of the 9E.03.

| 9E.03 | 9E.04 | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

9E series gas turbines can run on 52 types of fuel.

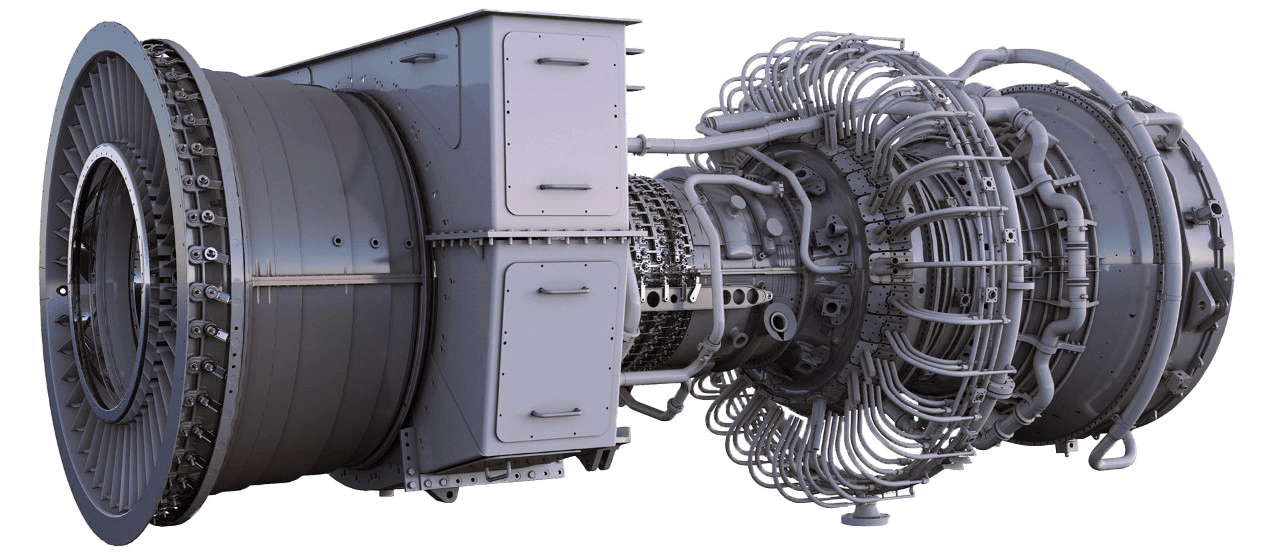

LMS100

A single, economical solution for the dispatch needs of nearly every industry condition.

| LMS100 PA+ | LMS100 PB+ | |

|---|---|---|

| Net output (MW) | ||

| Net heat rate (kJ/kWh, LHV) | ||

| Net efficiency (%, LHV) | ||

| Net heat rate (Btu/kWh, LHV) |

LMS100 gas turbines can start up in 8 minutes

7E

The 7E.03 gas turbine is recognized as an industry leader for 60 Hz industrial power applications. Its robust architecture and operational flexibility make it well-suited for a variety of peaking, cyclic, and baseload operations. With state-of-the-art fuel handling equipment, multi-fuel combustion system options, and advanced gas path features, the 7E gas turbine can accommodate a full range of fuel alternatives while helping to deliver better efficiency and lower emissions than other technologies in its class.

| 7E.03 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

7E series gas turbines can deliver 100% load in 10 minutes.

6F

GE Vernova’s 6F gas turbine offers the superior performance, reliability, and flexibility typically associated with larger power plants. Our 6F gas turbine packs big power into a small package, offering durability and flexibility for harsh, remote, or floating power environments. Whether it be for 50 or 60 Hz, the 6F gas turbine can maintain enhanced output and exhaust energy for combined cycle and CHP performance. The 6F offers segment-leading 32,000-hour combustion and hot gas path inspection intervals.

| 6F | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6F gas turbines offer fuel flexibility and hydrogen capability while maintaining the reliability you’ve come to depend on

LM6000

A leader in the +40 MW space, the LM6000 has over 40 million operating hours and more than 1,300 units shipped.

| LM6000 PG | LM6000 PF | LM6000 PF+ | LM6000 PC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM6000 gas turbines can start up in 5 minutes

6B

Its ability to operate in island mode, coupled with multiple decades of proven rugged performance, make the 6B an excellent solution for remote installations and extreme operating conditions. The rugged, reliable 6B heavy-duty gas turbine is a popular choice for refineries, natural gas liquefaction power, CHP applications, and industrial power.

| 6B | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

6B gas turbines can operate on a wide range of non-standard gas or liquid fuels, including over 90% hydrogen

LM2500

The LM2500 family of aeroderivative gas turbines boasts several times the operating experience of its competitors combined, and its flexibility and reliability are unsurpassed.

| LM2500XPRESS +G4 DLE | LM2500XPRESS +G5 DLE | LM2500 +G4 DLE | LM2500 +G4 SAC | |

|---|---|---|---|---|

| Net output (MW) | ||||

| Net heat rate (kJ/kWh, LHV) | ||||

| Net efficiency (%, LHV) | ||||

| Net heat rate (Btu/kWh, LHV) |

LM2500 gas turbines feature >99.8% availability

TM2500

Introducing one of the world’s most modular, reliable, and experienced mobile gas turbines.

| TM2500 | |

|---|---|

| Net output (MW) | |

| Net heat rate (kJ/kWh, LHV) | |

| Net efficiency (%, LHV) | |

| Net heat rate (Btu/kWh, LHV) |

TM2500 gas turbines can be installed and commissioned in 11 days

Gas turbine benefits

Fast, flexible, and sustainable

Our heavy-duty gas turbines are proven performers, and our aeroderivative gas turbines also feature industry-leading performance. With their unmatched fuel flexibility, their ability to complement renewables, and their fast startup and installation, GE gas turbines are a great choice for a variety of industries and applications.

Up to 100% H2 capability

As quick as 5 minutes start time

As few as 14 days installation & commissioning

Over 7,000 units worldwide

Efficient, versatile and reliable

Power generation that fits your needs

GE’s aeroderivative and heavy-duty gas turbines feature an output range from 34 MW to 571 MW. They are proven performers in simple and combined-cycle operation for pure power generation, cogeneration, mechanical drive, and waste-to-power. Whether you're generating power for large facilities or entire cities, electrifying your own operations, or are facing an emergency electricity shortage and need power fast, we can act as a versatile gas turbine supplier, ready to quickly provide a range of solutions.

A pioneer in aeroderivative and heavy-duty gas turbine technology

GE’s technology heritage is unparalleled in the power generation industry. Over the past 60 years, we’ve leveraged material science innovations from our aviation heritage to get increased performance at high firing temperatures. We were the first gas turbine manufacturer and supplier in the world to introduce single-crystal alloys, and we’ve devoted 15 years to developing ceramic matrix composites. As the industry leader in burning unconventional gas, GE introduced the first F-class gas turbine to use Arabian Super Light crude. In addition, we invented the Dry Low NOx (DLN) combustion system more than 30 years ago to reduce emissions—and it’s still being used today.

These advancements translate to both more power and more efficiency, which reduces lifecycle costs and enhances profitability for our customers. We continue to let innovation drive our company's product development, using a global exchange of knowledge, ideas, and tools—which we call the GE Store—to generate technology improvements and never-before-seen breakthroughs in gas turbine technology.

Experience you can count on

GE’s rich power generation history includes more than 60 years of supplying gas turbine technology. More than half the global gas installed base is from GE, with >7,000 gas turbines representing >800 GW of installed capacity in more than 120 countries.

The heavy-duty and aeroderivative gas turbine models GE manufactures and supplies in the United States, Europe, and throughout the world are proven performers in a range of applications, capable of achieving world-class gas turbine efficiency with next-generation capabilities.

On-demand webinar

Fast, flexible, sustainable power: Aeroderivative gas turbines for Munis & Co-ops

Today’s energy transition is creating challenges for all power producers, from local municipalities and Co-ops to utilities of all sizes. Operators need to plan carefully to ensure grid reliability and faster, cheaper, cleaner power for their end users.

Solutions

Explore our solutions

- By need/application

- By Industry

Want to learn more about how we can tailor a power solution that’s right for you? Contact us to get started.

Featured case study

Hear from our customer

Egypt

A first for Africa: LM6000 runs on hydrogen fuel blend

5 months

project duration

100

hydrogen capable GE gas turbines

"The combination of EEHC’s commitment and facilitation, GE’s global, industry-leading expertise in hydrogen-fueled power projects, and Hassan Allam and PGESCO’s strong on-the-ground construction and engineering capabilities, led to the extraordinary achievement of the safe, on time, and successful completion of this demonstration pilot."

H.E. Dr. Mohamed Shaker El-Markabi

Minister of Electricity and Renewable Energy of Egypt

Videos

Learn more about our gas turbines

Take a look inside our Greenville, South Carolina test stand facility.

GE’s HA plants are the most efficient in the world.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usDecarbonization - the future of energy

See how Gas Power is helping to build a world that works.

Learn more

© 2024 GE Vernova and/or its affiliates. All rights reserved.