Benefits

Increased profitability, improved O&M costs

Today’s combined-cycle plant operators are facing critical component wear and tear due to equipment age and increasing cyclic duty. As a result, plant output and efficiency are on the decline and unplanned emergent work is becoming more common. But with an ASP upgrade, you will experience better steam flow, improved O&M costs and reduced life consumption—which will help keep you online and profitable for years to come.

ASP benefits

- Reduced risk of unplanned outages and major emergent repairs during planned outages that are both costly and extend outage duration

- Increased steam turbine output based on recovery of aging losses and improved technology

- Enables combined-cycle plant upgrades that increase steam flow

- Improved combined-cycle heat rate

ASP features

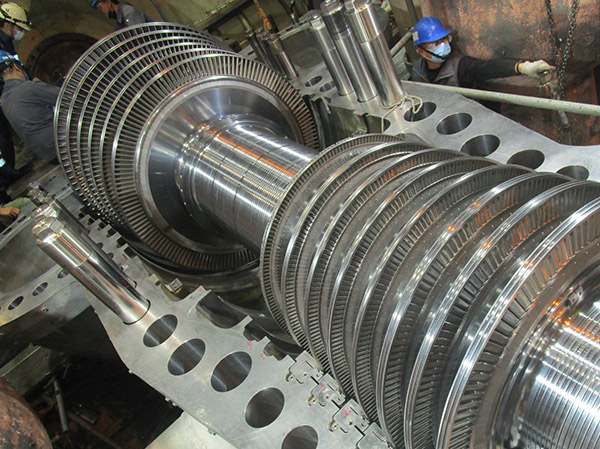

What’s involved in an ASP upgrade?

An ASP upgrade includes:

- Singlet** diaphragms in the HP and IP sections

- Modern N2 packing head configuration made of 9-Cr material with reduced axial loading and improved clearances

- Enhanced sealing features including HP tip and root J-seals, N2 packing head brush seals, IP tip brush seals

- The new steam path is designed to fit within the existing shell

Consider your options

Is an ASP Lite upgrade better for me?

If you aren’t experiencing any bending, cracks or other major issues with your steam generator rotor, a partial steam path upgrade (ASP Lite) is a better option than replacing your entire rotor. The ASP Lite upgrade addresses multiple TILs with a solution that includes improved materials, blade profiles, and advanced sealing for improved thermal efficiency. The new steam path provides improved reliability, availability, thermal efficiency for increased MW output, and reduced plant heat rate.

slide to see more

D10/D11 hardware repair and upgrade package summary

| Package 1 Component Repair |

Package 2 Advanced Steam Path "Lite" |

Package 3 Advanced Steam Path |

Package 4 Advanced Steam Path "Plus" |

|

|---|---|---|---|---|

| Package scope |

|

|

|

Package 3 plus:

|

| Customer benefits |

|

|

|

Package 3 plus:

|

| Address TILS | Short Term | Yes | Yes | Yes |

| Address rotor bow | Short Term | Good | Better | Best |

| ST MW output gain** (fleet average) |

None | To be confirmed (potentially Up to 0.9%) |

Up to 2.2% (1.2596) |

Up to 2.2% (1.25%) |

| CC HR improvement** (fleet average) |

None | To be confirmed (potentially Up to 0.3%) |

Up to 0.7% (0.495) |

Up to 0.7% (0.496) |

| Estimated outage days | 35-55 days | 25-30 days | <35 days | TBD |

| Operational flexibility | None | Minor tuning of HP/IP swallowing capacity | Enhancement of plant upgrades (GT, HRSG, etc.) | Package 3 Plus:

|

| Estimated delivery cycle | N/A | 40-45 weeks | 45-65 weeks (32 weeks for shell 2) |

65 weeks |

** Trademark of General Electric Company